The construction project is of key importance for Pakistan in terms of energy policy and also represents closer cooperation between Pakistan and China. The dam is being built on the Indus River in northern Pakistan and will form a reservoir approximately 40 kilometers downstream from Chilas. The world’s largest dam is planned to be 272 meters high and is expected to use 17.1 million cubic meters of roller-compacted concrete and 1.5 million cubic meters of ordinary concrete.

Twin-shaft batch mixer – the optimal choice

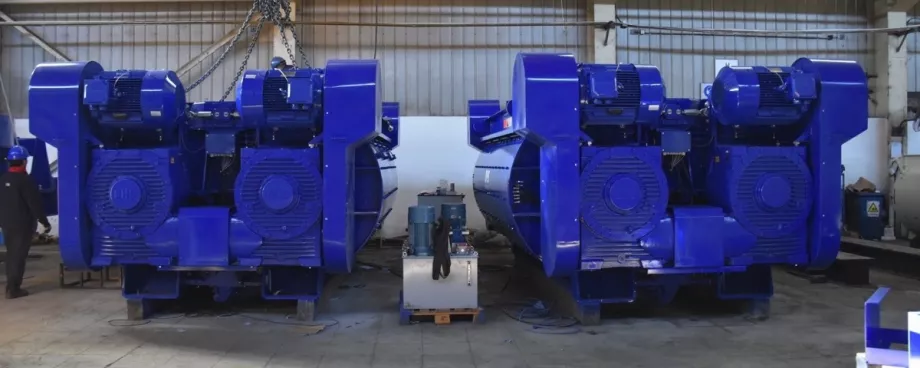

BHS-Sonthofen in Tianjin received a contract to supply a total of six BHS twin-shaft batch mixers for this major project, two of which are already constructed and delivered. The delivery includes four mixers of type DKX 7.00 with 7 m3 of hardened concrete per batch and two mixers of type DKX 6.00 each with 6 m3 of hardened concrete per batch.

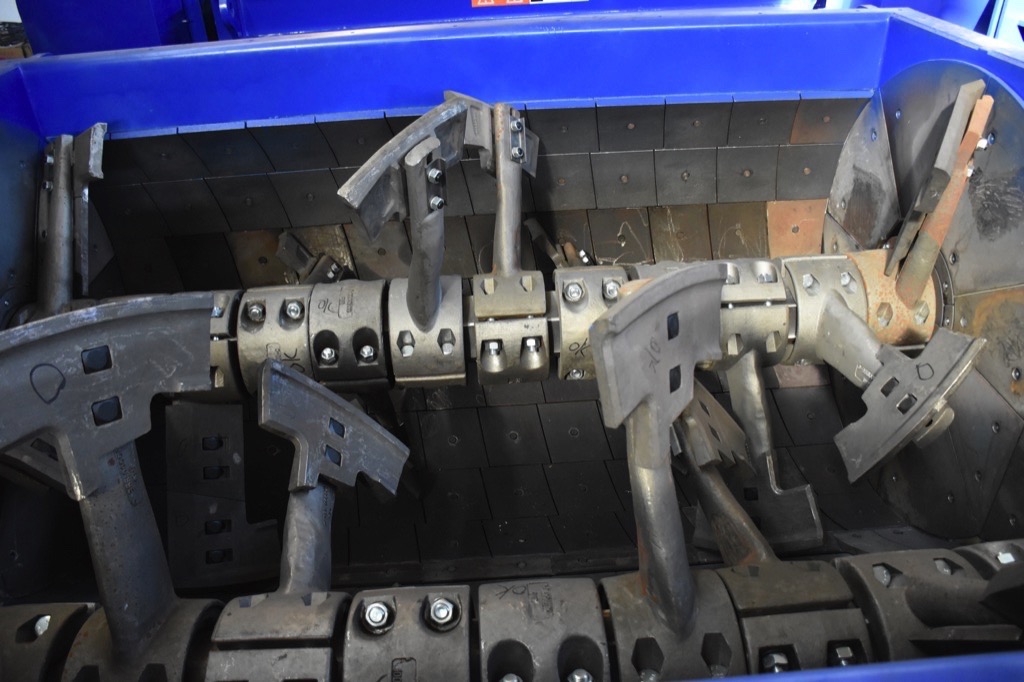

Ronny Laux, General Manager at BHS-Sonthofen’s Tianjin site, is responsible for the construction and delivery of the mixers: “The hydraulically bound base layers required for the dam, also known as ‘roller compacted concrete’ (RCC), must withstand the heaviest of loads. Our mixers are designed to handle demanding mixing tasks. The twin-shaft batch mixers meet the highest demands for mix homogeneity and reproducibility, even with large quantities – ensuring optimum concrete quality.” The low wear on the mixing tools and the mixing trough lining (thanks to the low speeds and compact design) contributes to the fact that the machines are in high demand for large projects in particular.

Additional mixers are planned

Two of the mixers manufactured in Tianjin have already been built and delivered to the large construction site. The remaining four are due to follow by the end of the year. The cooperation with BHS-Sonthofen went so smoothly that the customer suggested the prospect of a follow-up order even before delivery. “BHS is expected to deliver another six mixers next year,” says Laux, commenting on the progress of the project. “Having a location in Tianjin allows us to combine our expertise with regional proximity to the customer – this creates trust. Maintenance services can be provided or spare parts can be delivered quickly and easily.” According to the current plan, the dam’s construction period will end in 2029. ■