Re: Blending Coal At Thermal Power Stations

Idear sounds good, but bit confusing. Can you please represent in a layout format ■

Re: Blending Coal At Thermal Power Stations

The technique is quite normal practice: provided your port logistics match the single stockpile capacity. ■

Blending Coal

The power plants are not at ports. They receive coal by rail.

As arrival of of coal received from assigned coal mines and from ports is at random, It is not possible to make a single blended stockpile.

Only solution appears to be to have independant stockpiles for low calorific value Indian Coal and high calorific value imported coal. The reclaim systems (with crushers to size the material) form these stockpiles should take coal to two intermediate silos. The silo discharge systems (with weighfeeders or equivalent controls) will feed coal on a common conveyor leading to bunkers ahead of coal mills.

This is not a perfect blending system, but best that can be achieved in the present circumstances. ■

King Coal

As arrival of of coal received from assigned coal mines and from ports is at random, It is not possible to make a single blended stockpile.

Only solution appears to be to have independant stockpiles for low calorific value Indian Coal and high calorific value imported coal. The reclaim systems (with crushers to size the material) form these stockpiles should take coal to two intermediate silos. The silo discharge systems (with weigh feeders or equivalent controls) will feed coal on a common conveyor leading to bunkers ahead of coal mills.

This is not a perfect blending system, but best that can be achieved in the present circumstances.

==========================================================

Greetings and salutations Vinayak

I am thinking that a high horse power hammer mill for your coal prior to the stoker is in order for your stock pile to grind it below thirty mesh and in the process be able to get all the heat energy out of it at a low cost and in the process reduce your coal use and waste.

grinding it brings it down to its smallest size and greatest burning potential with a smaller fly ash and slag output.

Do you have a bag house for fly ash collection?

lzaharis ■

Re: Blending Coal At Thermal Power Stations

"Coal from imported sources will be moved from the port to the power plant by the state railway system."

By port logistics I meant the port logistics. Coal can be, must be, unloaded in the least time & either stored or transported. If you cannot match vessel capacity to individual demand, which is difficult/impossible then the intermediate logistics become quite important.

Unless you have available a free & inexhaustible rolling stock then you will incur demurrage costs unless the delivery rate closely matches the blending demand & storage capacity at the power plant. ■

Re: Blending Coal At Thermal Power Stations

I have tried to post this thread thrice but somehow it does not appear.

This is a query with regard to requirement of blending of coal in existing power stations whose coal handling plants are not designed considering blending.

The power stations are linked to specific mine and coal is brought to the power plant in captive railway system and unloaded in track hopper . Each station has minimum two track hoppers. Coal received is (-)250 mm size. This coal is conveyed to a crusher house where ist size is reduced to (-)20 mm.

After crusher house coal can be conveyed either to stockyard or to boiler bunkers. Coal reclaimed from the stockyard cannot be sent back to the stockyard and can go only to bunkers.

Each power plant has a stockyard with minimum 15 days coal consumption volume. Minimum two nos rail mounted ,travelling, cantilevered boom, slewing and luffing bucket wheel type stacker cum reclaimer operating in conjunction with a tripper are provided over two nos yard conveyors which serve to bring coal to the S/R for stacking as well as receiving reclaimed coal. These two yard conveyors feed coal onto common reclaiming stream of conveyors which carry coal to the boiler bunkers. Essentially ant blending requirement must be met either during the process of stacking or has to achieved during reclaiming. The stockpile cross section is trapezoidal with a base of 37 metres and a height of 10 metres. Minimum four such piles each of 500 metres length are available.

Since there is a steep shortfall in supply of coal from linked mine import of coal may have to be resorted to. The linked coal has a calorific value in the range of 3000-3500 Kcal/kg while the imported coal is likely to have a calorific value of 6000 Kcal/ kg. Since the boiler is not designed to receive such high calorific value coal, there is need to blend it with linked mine coal.

Coal from imported sources will be moved from the port to the power plant by the state railway system. The arrival of rakes by this system cannot be predicted and coal as and when received in rakes either single or bunched will have to be unloaded and sent to stockpile. Hence a planned creation of blended stockpile using chevron or windrow method of linked and imported coal may not be feasible.

What is thought of is to keep 3 piles of linked mine coal and one pile of imported coal and use both S/Rs in reclaiming mode and adjust the capacity in line with blend requirement and feed the reclaimed coal onto the reclaim conveyor which will carry one layer of imported coal with another layer of linked coal (Since both yard conveyors will be feeding a common reclaim conveyor. Now, this reclaimed coal will reach the boiler bunker after passing through 3 transfer points passing through chute work in each transfer point and hopefully getting mixed up reasonably.

Is it likely to work?

Any suggestions.

G.Ravindra

Sir i made an concrete effor to help you in finding out the panesea for your problem . before that may i know your objective to blending the coal . the point is i just want to orient with the hidden cue and concept of blending the coal

guddu ■

Blending Coal

Hello G.Ravindra,

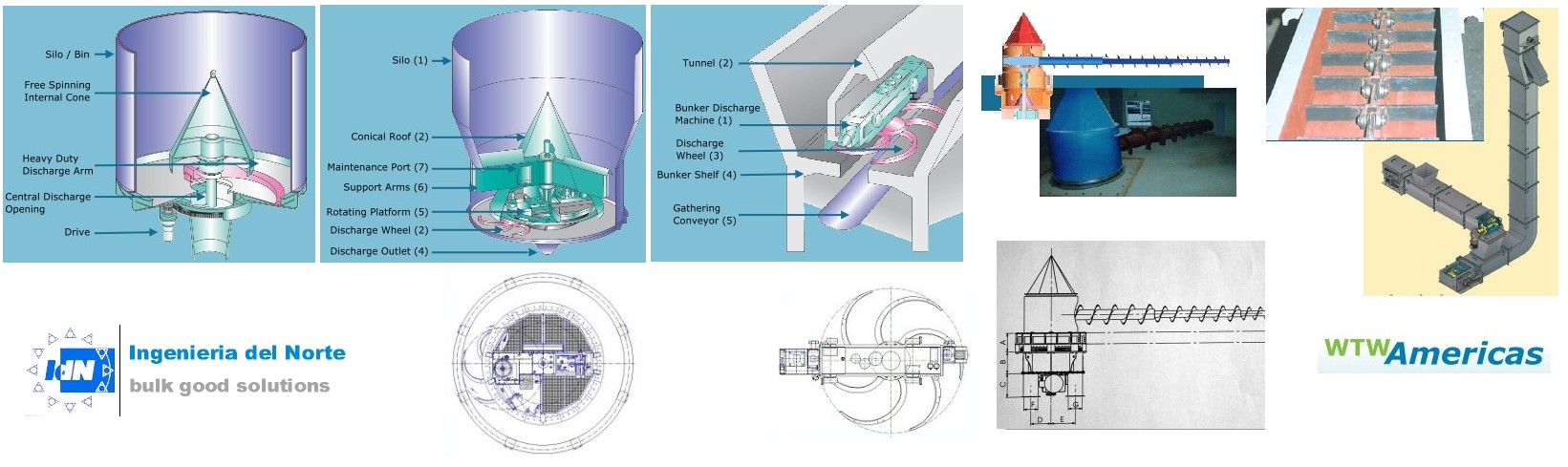

I am checking if it is possible to blend coal from the bunker with an BDM bunker discharge machine; the bunker has compartments with different coal sizes and quolities and the BDM could blend it; it is important to check the fire and explosion protection

See a few pictures below

Regards

dirk tannebaum

href="mailto:bulk.good.solutions.ar@gmail.com">bulk.good.solutions.ar@gmail.com

buenos aires - argentina

Attachments

idn-wtw_tkf-cadena-cajones_aplicaciones (JPG)

idn-wtw_bdm-bunker-aplicaciones_bunkerx3 (JPG)

■

Re: Blending Coal At Thermal Power Stations

I am checking if it is possible to blend coal from the bunker with an BDM bunker discharge machine; the bunker has compartments with different coal sizes and quolities and the BDM could blend it; it is important to check the fire and explosion protection

See a few pictures below

Regards

dirk tannebaum

bulk.good.solutions.ar@gmail.com

buenos aires - argentina

These are Louise machines, very good for extracting at different points simultaneously to achieve good blending, more than 1 machine is required.

Our man's problem is trying to blend overhead prior to extraction. He has to stockpile & cannot reasonably afford to build a bunker of the necessary capacity. Besides that he would have to incorporate a recirculation facility to recycle the material extracted by a Louise machine while the machine reaches a working point which provides the blend.

All this is well known ensilement technology which ought to be considered when selecting stockpile machines. Matching system characteristics to the available logistics is much more tedious than it is techologically demanding.

Spreadsheets make it a doddle.  Ravindra: Start one & see where it leads you in your blending quest. ■

Ravindra: Start one & see where it leads you in your blending quest. ■

Re: Blending Coal At Thermal Power Stations

Dear Mr. Ravindra

what you have written it is possible but some points you have to taking care

i.e.

what blending ratio you required?

if it is 50% & 50% then both yard conveyor can blend it properly but if the ratio is not equal than you have to taking care of that.

one other option we have that is you should instal a barrel reclaimer for blending if space is available.

G. Pandey ■

It's A Barrel Of Fun Now.

For the 4th time this year already. What's with the Indian obsession with drum reclaimers?

If the coal that you need to constitute the desired blend is somewhere behind an intermediate stock of other stuff then your man is stuffed out of sight.

Unless you can provide him with a 400 tonnes capacity helicopter...and means to clean the tracks at the landing site.  ■

■

Re: Blending Coal At Thermal Power Stations

Hi Ravindra

The blending system you have planned is obsolutely correct to ur present situation and as far as execution is concern a special care is to be taken for blending coal of two different grades i.e ratio like 25% & 75%.

While reclaming from two stacker of different grade coal u have to instruct ur both stacker operators to reclame at particular TPH i.e depending on ratio of blending and belnding exactely of 25% & 75% is quite difficult that may vary upto 10% on either side. So it is suggested to plan proper proportions to match boiler requirement i.e some where in between 3000 to 3500 kcal/kg.

There is another option like u can buy mobile hopper and fix it on yard conveyor i.e near required stock pile and feed coal with help of loader and u can achive better blending. This mobile hopper is very much usefull in case one stacker is busy in stacking coal which u cannot feed directly to bunker.

I personally feel that stacking different grade of coal in two bunker and the discharging to common conveyor what ever ration, there may not be proper blending.

Pl let us know what proedure ur have adopted and what r the results.

RK

India. ■

A Lekker Tikkie Drai !

....................

There is another option like u can buy mobile hopper and fix it on yard conveyor i.e near required stock pile and feed coal with help of loader and u can achive better blending. This mobile hopper is very much usefull in case one stacker is busy in stacking coal which u cannot feed directly to bunker.

.......

RK

India.

Then you will have to drive the stacker through the hopper more often than not.

You will also need a digger driver with enough bottle, or daft enough, to operate a high level bucket on a slope of 38 degrees while on full lock.

Or are there no safety regulations in your neck of the woods?? ■

■

Blending Coals Using On-Line Analysis Control

Hi Ravindra,

If your materials handling system is capable of stacking the coal according to its quality and the blending it in varying proportions based on an external control philosophy, then real time analysis could help you. There are many technologies suited to coal analysis in real time on conveyed flows. Scantech has a range of analysers, some using DUET (dual energy transmission), natural gamma, and PGNAA (prompt gamma neutron acivation analysis) that allow real time, non contact, full stream, continuous analysis of components such as ash, CV, elemental composition eg S, Cl, Fe, Ca, etc, and moisture (using microwaves). Many units are instalkled at power stations to control which coal goes to certain boilers. An analyser in conjunction with flow diverters can be used to bulk sort the coal onto various stockpiles which can then be reclaimed to a recipe (in your case CV) monitored by another analyser and controlled by an external console or your existing control system.

This ensures that a consistent quality of coal reaches each boiler assuming you have sufficient stockpiles of the required materials for the blend. We would be happy to discuss further with you. e-mail: h.kurth@scantech.com.au & web site: www.scantech.com.au ■

Re: Blending Coal At Thermal Power Stations

louispanjang

Then you will have to drive the stacker through the hopper more often than not.

You will also need a digger driver with enough bottle, or daft enough, to operate a high level bucket on a slope of 38 degrees while on full lock.

Or are there no safety regulations in your neck of the woods??

Sir louispanjang,

I suppose u miss took whole concept and i was tell that with help of mobile hopper u fix the same on the of two different conveyors as per the requirement and it dose mean that u place hopper on the middle of stacker cum reclamer yard conveyor.

Secondly i would like to bring to ur kind notice that we have fixed hopper at the head end of the stacker cum reclamer yard conveyor and we are using the same as per operational requirement.

regards

RK

India ■

Re: Blending Coal At Thermal Power Stations

Dear Shri G Ravindra,

Your requirement is to introduce blending facility in existing coal handling plant. This would require certain modifications and introducing certain additional handling facility in present plant. If done in a proper manner, it could result in to minimum changes. The system so formulated has to take in to consideration

1) Material A and material B inflow may be simultaneous or not simultaneous.

2) Even if both the materials inflow line are working simultaneously, they would not be working in exactly synchronized manner sustaining set proportions at all the time.

3) When both the inflow lines are active, their S/R machine will be preoccupied to deal with incoming material. So the supply of coal to boiler side will be under hold.

4) You may develop the system on the basis of aforesaid basic information. Specific system involves certain complex consideration and if need be, engineering services are available.

Regards,

Ishwar G Mulani.

Author of Book : Engineering Science and Application Design for Belt Conveyors.

Author of Book : Belt Feeder Design and Hopper Bin Silo

Advisor / Consultant for Bulk Material Handling System & Issues.

Pune, India.

Tel.: 0091 (0)20 25871916 ■

Blending Coal at Thermal Power Stations

Hello,

I have tried to post this thread thrice but somehow it does not appear.

This is a query with regard to requirement of blending of coal in existing power stations whose coal handling plants are not designed considering blending.

The power stations are linked to specific mine and coal is brought to the power plant in captive railway system and unloaded in track hopper . Each station has minimum two track hoppers. Coal received is (-)250 mm size. This coal is conveyed to a crusher house where ist size is reduced to (-)20 mm.

After crusher house coal can be conveyed either to stockyard or to boiler bunkers. Coal reclaimed from the stockyard cannot be sent back to the stockyard and can go only to bunkers.

Each power plant has a stockyard with minimum 15 days coal consumption volume. Minimum two nos rail mounted ,travelling, cantilevered boom, slewing and luffing bucket wheel type stacker cum reclaimer operating in conjunction with a tripper are provided over two nos yard conveyors which serve to bring coal to the S/R for stacking as well as receiving reclaimed coal. These two yard conveyors feed coal onto common reclaiming stream of conveyors which carry coal to the boiler bunkers. Essentially ant blending requirement must be met either during the process of stacking or has to achieved during reclaiming. The stockpile cross section is trapezoidal with a base of 37 metres and a height of 10 metres. Minimum four such piles each of 500 metres length are available.

Since there is a steep shortfall in supply of coal from linked mine import of coal may have to be resorted to. The linked coal has a calorific value in the range of 3000-3500 Kcal/kg while the imported coal is likely to have a calorific value of 6000 Kcal/ kg. Since the boiler is not designed to receive such high calorific value coal, there is need to blend it with linked mine coal.

Coal from imported sources will be moved from the port to the power plant by the state railway system. The arrival of rakes by this system cannot be predicted and coal as and when received in rakes either single or bunched will have to be unloaded and sent to stockpile. Hence a planned creation of blended stockpile using chevron or windrow method of linked and imported coal may not be feasible.

What is thought of is to keep 3 piles of linked mine coal and one pile of imported coal and use both S/Rs in reclaiming mode and adjust the capacity in line with blend requirement and feed the reclaimed coal onto the reclaim conveyor which will carry one layer of imported coal with another layer of linked coal (Since both yard conveyors will be feeding a common reclaim conveyor. Now, this reclaimed coal will reach the boiler bunker after passing through 3 transfer points passing through chute work in each transfer point and hopefully getting mixed up reasonably.

Is it likely to work?

Any suggestions.

G.Ravindra ■