Re: Pneumatic Transport Of Quartz Sand

Dear Neval,

A life span of 10-15 days does not say much. A better approach is how many conveyed tons or operating hours.

In pneumatic conveying, quartz is a very abrasive material and valves do not like that.

The abrasiveness is magnified by the quartz velocities.

Therefore, the first option to minimize wear is by designing the pneumatic conveying system for the lowest possible velocities.

Whether your system is optimal for this condition can only be assessed by reviewing the installation data and performance parameters. (Installation geometry, air flow, capacity and pressure and particle size)

If you like to have the velocities calculated, please supply the installation data.

The location of the considered valve is also important.

Just after the pressure tank, a very high, instantaneous velocity occur at the opening moment of the discharge valve. (especially when the opening pressure is very high).

The type of valve (which you did not mention) is also relevant.

Pinch valve: No obstruction in the material flow when open. Initial wear of rubber sleeve after a while, with the risk of quartz entering the control pressure system when the sleeve is worn through or burst.

Slide- or knife valves: Do not close properly in material applications.

Butterfly valves: Often used in pneumatic conveying installations. To protect the face of the butterfly, often a round bar or half-round plate is welded in front of the butterfly in open position, protecting the disc side against impact. A replaceable round bar in two opposite sockets with plug is also a solution.

Other types of valves s.a. ball valves, dome valves, etc, I expect that those types of valves will wear because of opening and closing with trapped quartz between the seals rather than wear by the passing quartz.

If you need more information, let us know.

Have a nice day

Teus ■

Teus

Re: Pneumatic Transport Of Quartz Sand

Kindly give more details i.e. lean phase or dense phase system. Where the valve is placed in the system, what kind of valve is it.

Once a bit of detail is know some alternatives can be looked at. ■

Clyde Bergemann Power Group Extreme Rotary Valves

Dear Friends,

Our Extreme Rotary Valves is considered the valve of choice by customers who demand long life, rugged durability, ease of maintenance and high quality.

Additional features are:

Standard Design rated for temperatures up to 500 degrees F

High Temp Design rated for temperatures up to 1000 degrees F, includes:

High Temperature Outboard Mounted Bearings

Donex Motor Heat Shield

High Temperature Paint

Internal Burst Pressure rating of 75 PSIG ( Follows NFPA Guidelines)

Good for differential pressure up to 25 PSIG (additional options required)

Sizes 6” to 24”

Available Options:

Shaft Zero Speed Switch (Proximity Type or Shaft Mount)

Shaft Air Purge Kit with Flow Meters

Variable Frequency Drive Controllers (For Speed Control & Reversing)

Inlet Deflection Shear Plate (For Large Particle Sizes)

Vent Hoppers (for the venting of displaced air on a pneumatic conveying system)

Mechanical seals for high pressure applications

Also, our PERMA/flo abrasion resistant pipe and fittings:

Designed to withstand the wearing action of abrasive materials when they are transported either hydraulically or pneumatically.

Constructed of a hard chrome-iron, abrasion resistant alloy Available in hardness ranges to 500+ Brinell compared to #140 for 316 SS, #180 for gray cast iron.

Cast solid, not surface hardened which could wear off over time.

The compact construction of the fittings allow easy installation and replacement.

Available in sizes ranging from 2” to 12”.

All PERMA/flo Pipe & Fittings are cast with plain ends to allow for a multitude of connection options including sleeve type couplings and flanged adapters.

Please contact me if you want more information about our product and services at:

href="https://forum.bulk-online.com/attachment.php?attachmentid=31408&d=1326207034" title="Name: Low Res - CBDDEXTREME FEEDER.pdfViews: 368Size: 785.8 KB">Low Res - CBDDEXTREME FEEDER.pdf

■

Re: Pneumatic Transport Of Quartz Sand

href="https://forum.bulk-online.com/attachment.php?attachmentid=33259&d=1340610251" id="attachment33259" rel="Lightbox75014" target="blank">■

Problems With Valves In Pneumatic Transport Of Quartz Sand.

href="https://forum.bulk-online.com/attachment.php?attachmentid=33920&d=1346770538" id="attachment33920" rel="Lightbox75816" target="blank">

Mike Griffiths

Omegaslate UK Limited

2 Chirk Close

Forest Gate

Kidderminster

Worcestershire

DY10 1YG

Tel : +44 (0) 1562 755 824

Fax : +44 (0) 1562 742 979

Mobile: 07836 748 588

Web Site at:

href="http://www.omegaslate.com" target="blank">www.omegaslate.com

Attachments

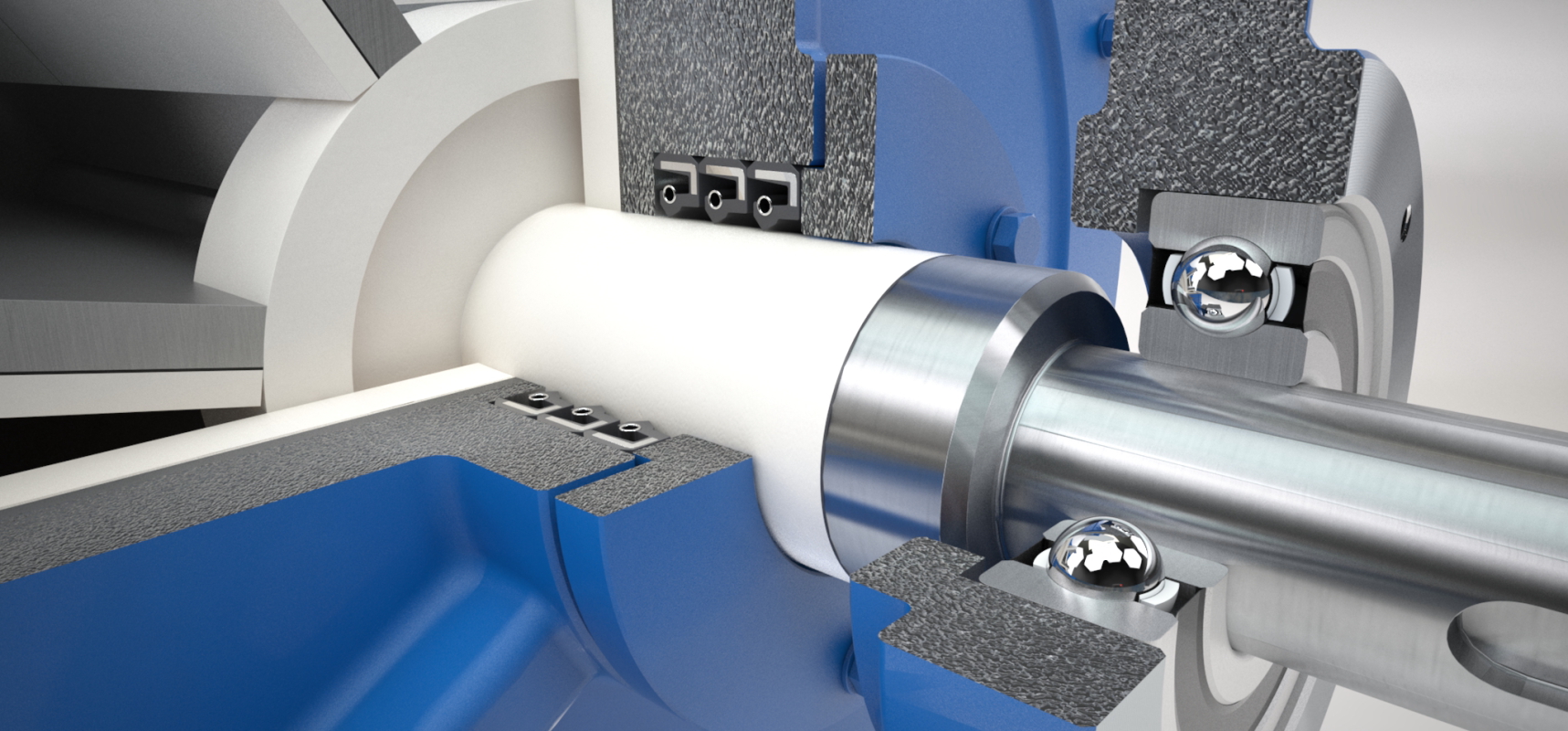

j6 (2)assembly1assembly1 (JPG)

■

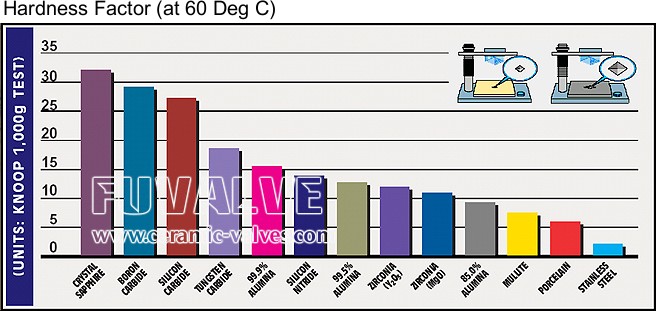

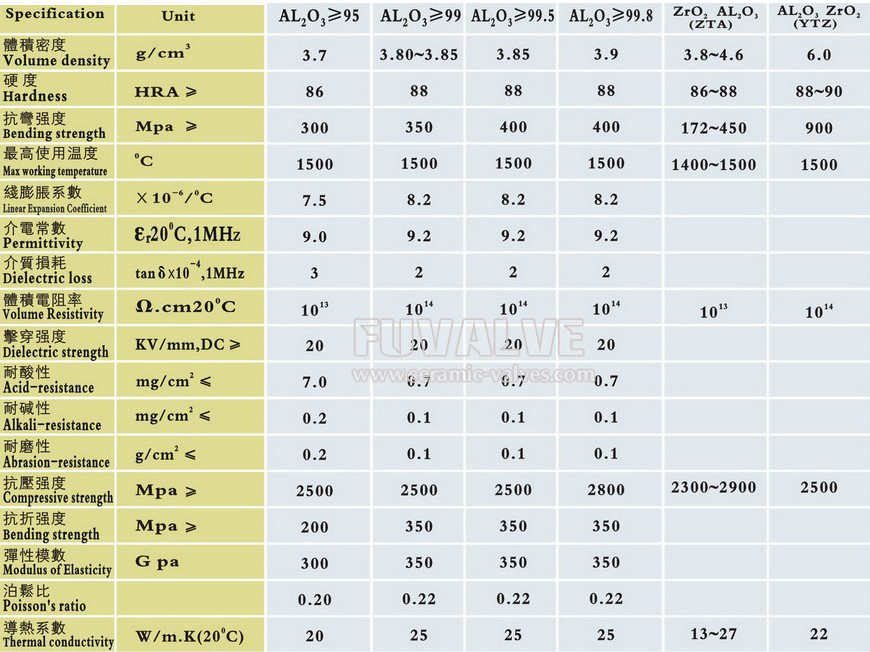

Ceramic Ball Valve

To use a ceramic lined ball valve to solve the problem.The hardness of Al2O3 ceramics and ZrO2 ceramics can reach HRA 86-88.You'll find something help at www.ceramic-valves.com ■

Re: Pneumatic Transport Of Quartz Sand

How about use the ceramic lined valve... ■

Pneumatic Transport of Quartz Sand

Problems with valves in pneumatic transport of quartz sand

Dear Bulkoholics,

We have a clien who has a problem with valves 125 mm, 5''. Some wear for 10-15 days and must be replased. Proposal for valvas?

Best regards ■