General Kinematics Corp. (Continued)

General Kinematics in the Powder/Bulk Industries

Spiral Conveyors

Vibratory Fluidbed Processors

VIBRA-DRUM™ Grinding Mills

Omni-Screener™ Bulk Material Screener

Two-Way Feeders

Hula Hopper™ Bin Activator / Feeder

VIBRA-PACK™ Shipping Container Densifier

Attachments

■

General Kinematics Corp. (Continued)

Vibrating Spiral Conveyors

General Kinematics vibrating spiral conveyors for processing offer unmatched performance with added process features. Available in infinite lengths and heights, GK spiral conveyors are custom built for your specific application.

Technically advanced vibrating spiral conveyors do more than just move your product. Spirals can be equipped for direct or indirect drying, direct or indirect cooling, coating, and can be designed to convey material up or down. Available in stainless or mild steel, open or enclosed, there is no limit to what a GK spiral can do.

FEATURES

• Direct drive or two-mass designs available.

• Can be open or enclosed, depending on your application.

• Backed by GK's 100% process guarantee.

Attachments

■

General Kinematics Corp. (Continued)

Vibratory Fluidbed Processors

General Kinematics vibrating fluidbed processors are unmatched in bulk processing performance. Each fluidbed is custom engineered to match your specific process need. An array of options make GK fluidbeds a versatile part of your process operations.

General Kinematics vibrating fluidbed processors increase your throughput while enhancing your product quality. Capable of continuous or batch processing, each fluidbed is custom engineered to meet your specific process objectives.

FEATURES

• Can heat, cool, dry, coat, and more, all in one unit.

• Custom designed to meet your specific throughput requirements.

• Backed by GK's 100% process guarantee.

Attachments

■

General Kinematics Corp. (Continued)

VIBRA-DRUM® Grinding Mills

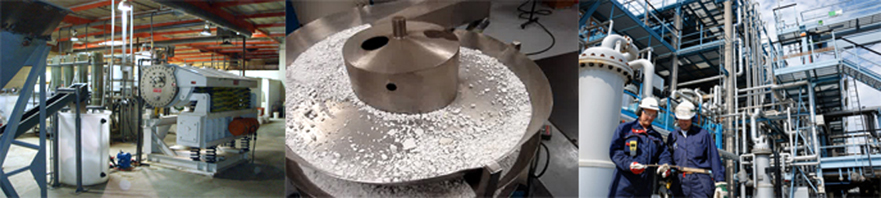

Vibra-Drum grinding mills are proven in dozens of milling applications in the mining and mineral industries. Grinding processors are achieving impressive energy savings (35-50%), thanks to a unique rotational material motion that is more efficient than conventional ball or rotary mills. New processes such as micron grinding and mechano chemical grinding give our customers a unique and effective competitive advantage.

Exceptional grinding performance and energy savings are the result of the Vibra-Drum's natural frequency design. A sub-resonant, two mass drive and spring system alternately stores and releases grinding power. Once in motion, energy is only needed to move the grinding media as a fluid mass, and to overcome frictional losses. The Vibra-Drum can be used for processes other than grinding. It has been used to process and agglomerate fiberglass, mix product components, clean castings, for hydrometallurgy, minerals recovery, and other processes.

Attachments

■

General Kinematics Corp. (Continued)

Omni-Screener™ Bulk Material Screener

General Kinematics vibratory Omni-Screener produces superior control and classifying results in bulk material processing applications. Units can have multiple deck surfaces for variable screening. Square shape makes screen changes a snap using simple tensioning procedures.

FEATURES

• Spiral flow of product from central infeed point develops extended residence time for near-size particles.

• Simple, self-contained, motorized drive with variable vibration amplitude and adjustable angle of attack permits rapid adjustments to achieve optimum screening efficiency.

• Low headroom construction can be totally enclosed where required.

• Available in carbon steel, stainless steel, and food grade construction.

Attachments

■

General Kinematics Corp. (Continued)

Two-Way Vibratory Feeders

Two-Way feeders from General Kinematics open up a wide range of process possibilities. The two-way's bi-directional conveyance allows you to alternate material flow for multi-directional product processing, for rejection of bad product, or any other process which may require multi-directional conveyance from a single unit. The units completely horizontal stroke shuffles material with no impact and a significant reduction in noise. Available in straight and all new bi-directional curved designs.

FEATURES

• Uses a single low horsepower drive, reducing energy consumption.

• Available in curves up to 90 degrees.

• Horizontal stroke does not damage fragile product.

Attachments

■

General Kinematics Corp. (Continued)

Hula-Hopper® Bin Activator / Feeder

The General Kinematics Hula-Hopper is an improved vibratory equipment concept based on operating principles proven in thousands of General Kinematics installations. Within a single, extremely low headroom unit, Hula-Hopper combines material activation, infinitely variable flow rate control, and positive flow shut-off. Yet installation, service, and operating costs are dramatically lower than for comparable systems.

Hula-Hopper eliminates many problems associated with more complex, brute force vibratory machinery because of its simplified operating design. As a two-mass vibratory unit, Hula-Hopper uses a low-horsepower motor drive, therefore electric power needs are minimal. Orbital action eliminates compacting and bridging because only material drawn out is activated.

FEATURES

• Infinitely adjustable flow control using GK's VF wheels or electronic VFD.

• Extremely low headroom design reduces height requirements.

• Easy to service design.

• Backed by GK’s 100% process guarantee.

Attachments

■

General Kinematics Corp. (Continued)

VIBRA-PACK™ Shipping Container Densifier

The VIBRA-PACK fills the full volume of your bulk containers to:

• Move bigger payloads.

• Use fewer containers per order.

• Dramatically reduce total shipping costs

Ship a full load of any bulk material typically pneumatically loaded into a universal bulk shipping containers. Actual load increases of over 25% have been realized after the release of trapped air!

FEATURES

• Attaches directly to container on trailer… no special containers or equipment needed.

• Manual or hydraulic clamping available

For more information, please visit:

href="https://edir.bulk-online.com/profile/1345-general-kinematics.htm" target="blank">https://edir.bulk-online.com/profile...kinematics.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=General+Kinematics+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

bulk-online Leader

Attachments

■

General Kinematics Corporation

General Kinematics Corporation

General Kinematics is the premier vibrating equipment supplier, with capabilities to engineer, design and implement solutions for critical production processes. At GK, our vibratory and rotary equipment is only part of the payoff. It is through the collaborative efforts of our customer relationships that both superior process and product emerge to improve customer profitability, productivity, and product quality . Below are some of the innovative solutions incorporating vibratory equipment technology available from General Kinematics:

Cooling, Heating, Coating, and Drying

General Kinematics' vibrating process solutions are exceptionally flexible for a wide range of granular solid and powdered materials and enable multi-functional processes including drying, heating, cooling and coating in a single continuous vibratory unit.

Densifying

Vibrating densifiers help fill the volume of your shipping containers using constant, controlled agitation during loading. Sustained vibratory motion settles material by allowing entrapped air to escape. Best of all, it’s all relatively noise-free!

Separating

GK has successfully applied their proprietary vibratory technology incorporating vibration, fluidization, pneumatics, and/or mechanical fingers to accomplish tough separating process objectives. Our extensive testing facilities for separation trials assist in the development of outstanding solutions to demanding separation challenges.

Grinding

Our vibratory processors produce an impressive energy savings of 35 to 50 % relative to conventional ball or rotary mills. Combined with lower installation and maintenance costs, the performance and economics of the General Kinematics vibrating processors are incomparable.

Conveying and Feeding

General Kinematics can configure vibratory conveying and vibrating feeding systems to fit into your existing process... no matter which direction your material flow needs to go. If you need your material to go up, down, left, or right, GK can apply vibratory technology to get it there efficiently.

We would like to demonstrate how our unique engineered solutions can be applied to your specific requirements, and ask that you call on our experienced staff for a free, confidential, no obligation, engineering consultation. To begin your process, please visit our website at

href="http://www.generalkinematics.com" target="blank">www.generalkinematics.com.

href="https://edir.bulk-online.com/profile/1345-general-kinematics.htm" target="blank">https://edir.bulk-online.com/profile...kinematics.htm

General Kinematics locations:

Headquarters

General Kinematics Corp.

5050 Rickert Rd.

Crystal Lake, IL 60014

office: 815-455-3222

fax: 815-455-2285

General Kinematics Process - Asia

1203 Tower 3

Beijing International Center No.3

No.38 Dong San Huan Bei Lu

Chaoyang District

Beijing, P.R. China 100026

office: 86-10-8587-9861

fax: 86-10-8587-9561

General Kinematics Foundry - Asia

Room B-702

Xin Da Building, No.322

Xian Xia Road

Shanghai, P.R. China 200336

office: 86-21-6289-6880

fax: 86-6289-6160

GK Europe GmbH

Wernerstr. 32

D-42285 Wuppertal

Germany

office: 49 (0)202 430 42 160

fax: 49(0)202 430 42 164

General Kinematics Ltd.

Dawley Brook

Brierley Hill

DY6 7BB

West Midlands

England

office : 44 1384 273303

fax : 44 1384 273404

General Kinematics India

Flat No 101 First Floor

Fort House

21st Cross, Coconut Gardens

Sir M Visheweshraia Nagar

T.C.Palya Main Road

Ram Murthy Nagar

Bangalore - 560 016

India

office: 91 80 2537 4611

fax: 91 9880 291 311

For more information, please visit:

href="https://edir.bulk-online.com/profile/1345-general-kinematics.htm" target="blank">https://edir.bulk-online.com/profile...kinematics.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=general+kinematics+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

On-Site Vibratory Equipment Training

General Kinematics commitment to our customer’s success continues even after the sale of equipment. GK offers our customers a wide range of training support custom tailored to meet your needs. With decades of experience in the industry and out in the field, our instructors are some of the most knowledgeable vibratory experts in the world.

VIBRATORY 101™ Maintenance Seminars:

If you already have a preventative maintenance program, but want to learn first-hand the best way to maintain your vibratory equipment, then sign up for General Kinematics VIBRATORY 101™ Maintenance Seminar. This FREE on-site class will teach your maintenance staff the best way to maintain vibratory equipment, how to detect and repair a problem, the basics behind the theory of operation, and more. Each program is tailored to your facility, product, and types of installed equipment.

Advanced Maintenance Seminars:

If you have already gone through the above program and are looking for even more detailed information, General Kinematics can provide you with a customized maintenance program specific to your facility requirements.

Contact Randy Smith, Vice President of Technical Services, to schedule your VIBRATORY 101™ session or other vibratory training today!

Office: 815-444-3522

Cell: 847-420-5306

rsmith@generalkinematics.com ■

General Kinematics Corp.

General Kinematics

General Kinematics Corporation, incorporated in 1960, was established to market, design, and custom fabricate innovative vibratory materials handling and processing equipment. Today the company is one of the world's largest suppliers of vibratory processing equipment, holding more than 200 worldwide patents, and is acknowledged as a major contributor to the technical advancement of vibrating equipment design and application.

General Kinematics serves a worldwide customer base through a network of engineering-oriented independent sales representatives who cover major industrial markets throughout the United States. International markets are serviced from subsidiary operations and through a combination of representatives, licensed manufacturers, and strategic alliances with leading industry specific organizations in other strategic locations. Today, over 50,000 General Kinematics units have been installed in virtually all of the world's industrialized countries.

As new process and efficiency challenges emerge, General Kinematics is uniquely qualified to address these needs with advanced technology, innovative engineering, new materials, and manufacturing techniques... all applied to improving customer productivity and profitability while meeting ever more stringent requirements.

Today, GK knows no limit in our ability to provide a broad level of engineering support and capacity that other companies cannot offer. We bring a 360-degree view to the whole process picture, often supplying engineering resources our customers do not have, or do not wish to fund internally.

For more information, please visit:

https://edir.bulk-online.com/profile...kinematics.htm

http://www.google.com/search?client=...UTF-8&oe=UTF-8

bulk-online Leader

Attachments

about_1 (JPG)

gklogo (JPG)

■