Berthold Technologies (Continued)

BERTHOLD TECHNOLOGIES Process Control is the specialist for non contact monitoring of process parameters such as density, level, moisture, bulk flow and analysers for online process analysis. These measuring instruments use x-rays or nuclear radiation from radioactive sources as well as microwaves. We provide technology, experience and facilities to manufacture radiation sources, shieldings, detectors and electronics.

Attachments

■

Berthold Technologies (Continued)

Continuous Level Measurement

The external mounting and the non intrusive arrangement of a continuous level measurement are some of the outstanding advantages, that determine it for various applications like:

• high- and low-pressure reactors

• agitated vessels

• bunkers

• autoclaves

• hot material containers, etc.

No matter, what the physical- and chemical properties of the measured product are nor what the shape of the vessel is.

Measuring Principle

The continuous Level Measurement operates according to the physical law of attenuation of gamma radiation, while it is passing through matter. Practically, the product to be measured is shielding the radiation coming from a radioactive source and according to the height of the product, more or less of the original radiation is reaching the detector. This measuring signal is then transfered to an output signal which directly correlates to the actual Level of the product.

Depending on the measuring arrangement, either a rod shaped detector or one of minor size is selected, both using the most efficient scintillation principle, which allows the use of lowest possible source activities. Under extraordinary conditions, even the use of a rod shaped detector in combination with a source of the same length is possible and will give the most accurate Level reading.

Nuclear measurement will not change the products being measured!

The measurement is independent of:

• High temperature

• High pressure or vacuum

• Volatile & biohazard material

• Corrosive material

• Agitators, baffles, coils etc.

• Build up on vessel walls

• Physical and chemical properties of the product and the process

Advantages:

• Non-contact, continuous measurement of the filling level

• Adaptable to all vessel shapes

• Level- or volume-proportional arrangement

• Measuring range up to more than 10 m

• Lowest source activity Automatic decay compensation

• Choice between Co-60 or Cs-137 as radiation source

• On line measurement

• No moving parts

• Reliable technology

• Low maintenance

• Easy to calibrate

1. Capsulated and shielded rod-source covering the whole measuring span

2. Point scintillation detector receiving the entire radiation field from the source

3. Two wire standard cable for data transmission

4. Evaluation unit with digital display, 0/4-20 mA analogue output and alarm outputs

Attachments

■

Berthold Technologies (Continued)

Level Switch Measurement

Level Switch applications are found in all types of production, including the food indutry, for monitoring one or more high/low levels on fluids or bulk material.

This is applicable on all kinds of vessels e.g.:

• storage tanks

• hot product bunkers

• stirrer vessels cyclones

• sluices

• feeder chutes etc.

Measuring Principle

The Level Switch system is based on the physical law of the attenuation of Gamma radiation as it passes through matter. In the case, there is product in between the source and the corresponding detector, the detected radiation decreases by a considerable extend. This effect corresponds to the product's presence or absence and therewith it is signalised whether the surveyed level is reached or not.

The measurement is independent of:

• High temperature

• High pressure or vacuum

• Volatile & biohazard material

• Corrosive material

• Agitators, baffles, coils etc.

• Build up on vessel walls

• Physical and chemical properties of the product and the process

Advantages

• Contactless measurement

• External mounting without modification of the existing vessel

• Lowest source activity

• Decay compensation

• Independent from chemical composition and most physical properties

• Suitable for aggressive products, high temperatures and high pressure ■

Berthold Technologies (Continued)

Density Measurement

The contactless and continuos measurement of the density of liquids or bulk material is requested in even more than the following applications:

• Concentration measurement of acid, alkali, saline solution and suspension

• Crystallisation and polymerisation monitoring

• Determination of the solid matter content in slurries, in flue gas desulphurisation suspensions, in aluminium production and in mining

• Measurement of the bulk density in washing powder and clinker

Measuring Principle

The Density Measurement operates according to the physical law of attenuation of gamma radiation, which is dependent from the radiation energy, the measuring path length and the density of the irradiated product. Through keeping the energy constant and since the measurement takes place in a pipeline, so the measuring path’s length is also constant, the attenuation is only dependent from the applicable density of the measured product. The radiation intensity, received from a sealed and shielded source is measured by a most sensitive scintillation detector and this measuring signal is then converted to a density or concentration measurement signal by the corresponding evaluation unit.

Dependent from the desired measuring range and accuracy and the products specification, the ideal irradiation angle is selected or a measuring path is used.

Nuclear measurement will not change the products being measured!

Measurement is independent of:

• Colour, viscosity, conductivity and most chemical properties of the product

Advantages

• Non-contact, continuos measurement of density or concentration

• Adaptable to all pipelines from 25 to 1000 mm

• Most simple installation on existing pipelines

• Measurement in vessels also possible

• Lowest source activity

• Automatic decay compensation

• High long-term stability due to electronic compensation of temperature and ageing influences

• On line measurement

• No moving parts

• Realiable technology

• Low maintenance

• Easy to calibrate

Flow Cell

Attachments

■

Berthold Technologies (Continued)

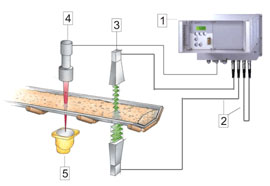

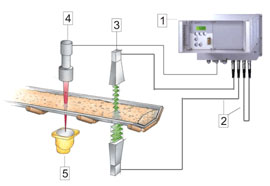

Bulk Flow Measurement

The contactless measurement and the lack of moving parts, allow a precise determination of the mass flow without any wear to the systems components. This outstanding advantage is applicable on various mechanical conveying systems like:

• belt conveyors

• screw conveyors

• troughed chain conveyors

• steel plate conveyors

• bucket conveyors

• free fall in chutes or pipes

This makes a radiometric bulk flow measuring system particularly interesting for various applications.

Measuring Principle

The intensity of radiation, coming from a specially designed radiation source, is measured by a scintillation counter after it has passed the material and the conveying system. From the resulting measuring signal, which is dependent from the loading on the conveyor system and the product speed, the evaluation unit calculates the mass flow rate.

Nuclear measurement will not change the products being measured!

Measurement is independent of:

• High temperature

• High pressure or vacuum

• Volatile & biohazard material

• Corrosive material

Advantages

• Contactless measurement

• External mounting without modification of the • existing conveyor system

• Lowest source activity

• No recalibration necessary

• Highest level of repeatability

• On line measurement

• No moving parts Low maintenance

• Easy to calibrate

1. Capsulated and shielded source which is mounted below the conveyor

2. Scintillation detector mounted opposite to the source

3. Measuring frame, installed on existing conveyor

4. Processor module with digital display, 3 relay outputs for signalisation and/or external totalizer, for wall mounting or 19’’ rack

5. Two wire standard cable for data transmission

Attachments

■

Re: Berthold Technologies

Neutron Moisture Measurement

For the continuos determination of moisture in bulk solids, the Neutron Moisture Measurement gives a representative moisture signal on applications like:

• sand moisture

• coke moisture

• sinter moisture

• calcareous limestone

No matter, what the temperature, pressure, pH value and colour of the material is.

Measuring Principle

The Neutron Moisture Measurement is based on the principle that fast neutrons are slowed down (or moderated) through their collision with Hydrogen nuclei. Thus, a cloud of slow neutrons is created around a source of fast neutrons coming from an Americium/Beryllium source, while the concentration of slow or thermal neutrons depends only on the hydrogen content in the measuring volume.

Nuclear measurement will not change the products being measured!

The measurement is independent of:

• High temperature

• High pressure or vacuum

• Volatile & biohazard material

• Corrosive material

• pH value and colour of the product

Advantages

• Continuous measurement of moisture content

• Detection of all water molecules, irrespective of their physical or chemical bond

• Simple installation in or on existing tanks, vessels or conveyors

• Large measuring volume, ensuring representative moisture determination

• Lowest source activity due to the use of most sensitive He-3 counter

• On line measurement

• No moving parts

• Realiable technology

• Low maintenance

• Easy to calibrate

1. He-3 counter tube, sensitive for thermal neutrons only

2. Capsulated Am/Be source, creating fast neutrons

3. Cloud of slow neutrons, moderated through the Hydrogen content

4. Two wire standard cable for data transmission

5. Evaluation unit with digital display, 0/4-20 mA ananlogue output and alarm outputs

Measuring application Measuring application

in bunker probe as surface probe

Attachments

■

Berthold Technologies (Continued)

Concentrations- und Moisture Measurement with Microwave System

Using the Microwave System from Berthold, the water content or dry content of fluids and solid matters can be measured online.

Depending on the application, various microwave sensors can be applied:

For example

• Insertion sensors for the measure-ment in process containers or crystallizers

• Pipeline sensors for the inline measurement in pipe.

• Horn antenna for the measurement on a conveyor belt or in a chute.

The suitable measuring arrangement can be configured by the wide spectrum of sensors.

Measuring Principle

The microwave irradiates the product with very little power (< 0.1 mW). The material components are polarised at different strengths and as a result of this, the microwaves lose on speed and energy. Thereby, the speed reduction brings about a phase shift and the weakening of the energy effects an attenuation of the microwave.

If there are free charged particles in the product or polar materials like water molecules H2O, then this effect is disproportionately intensified. The water influence is 40-times larger as the influence of other components. Hence, it is clear how selectively sensible the water components can be measured.

The Figure shows a microwave sensor or two antennae.

Radiometric area weight compensation can complement the measurement on bulk goods as an option, see arrangement 3. When strong fluctuations occur, the measuring accuracy can be increased considerably.

Advantages:

• High accuracy by selective sensitivity to water.

• Representative measurement by recording of the complete material interface.

• Simple installation by computerised sample taking and automatic calibration.

• Robust sensors, use of wear resistant materials.

• Contactless, dependeing on sesor.

• Very low amount of maintenance.

Examples of successful applications

Sugar industry

• Brix Measurement

Food Industry

•Butter

•Caramel

•Cream cheese

•Curd

Power Station Industry

• Gypsum suspension

• Milk of lime

Chemical Industry

• Acids

• Resin in Water

• Silicic Acid

• Synthetic solutions

Others

• Coking Coal

• Hard and Brown Coal

• Sand

• Wood Chips

For more information, please visit:

href="https://edir.bulk-online.com/profile/2287-berthold-technologies.htm" target="blank">https://edir.bulk-online.com/profile...chnologies.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=berthold+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

1 Evaluation unit incl. microwave module

2 High frequency cable

3 Microwave sensor: insertion probe, pipeline measuring cell or horn antenna.

4 Scintillation detector

5 Gamma source

Attachments

■

BERTHOLD TECHNOLOGIES

What we do:

BERTHOLD TECHNOLOGIES GmbH & Co KG is located in Bad Wildbad in the German Black Forest. In continuing a long and unequalled tradition of innovative and original contributions to the development of sensors, detection systems and instruments dating back to 1949, we offer high performance standard products, optimal solutions for specific customer applications and OEM instruments for Biosciences, Medicine, Industrial Process Control and Radiation Protection.

The original Berthold product line consisted mostly of sensors and detection systems for nuclear radiation and X-rays. However, by continuously following the requirements of our customers and with the progress of technology, the product lines were extended to measuring luminescent light and to the use of microwave radiation.

Our experience and know-how in physics and in techniques of highly sensitive detection of light, nuclear radiation and microwave frequencies, together with the use of modern electronics and software, allows us to maintain our excellent and long reputation as a competent partner in solving diverse and difficult measurement problems and as a supplier of innovative and up-to-date instruments of the highest quality and reliability.

We serve and support our customers with a worldwide distribution organization with emphasis on applications assistance and product maintenance.

Who we are:

Trustees of a long-term tradition

The original company was founded in 1949 in Bad Wildbad by Prof. Dr. Rudolf Berthold and was named “Laboratorium Prof. Dr. Rudolf Berthold”. In 1960, his son, Dr Fritz Berthold took over the management of the company until 1989, when the company was acquired by the US EG&G Inc. corporation, later named PerkinElmer Inc.

Eleven years later, (year 2000) the Berthold family, together with Hans J. Oberhofer, purchased the company from PerkinElmer Inc. The company is now named BERTHOLD TECHNOLOGIES GmbH & Co KG, with Hans J. Oberhofer as Managing Director and Dr. Fritz Berthold as Chairman of the Board. The company continues to be headquartered in Bad Wildbad with affiliated companies in Austria, Belgium, France, Great Britain, Italy, Switzerland and U.S.A. and the company is represented throughout the rest of the world by factory appointed distributors and representatives.

Three business units

The company is structured in three business units, namely Industrial Process Control, Bioanalytical Instruments and Radiation Protection Instrumentation. These units are aligned with the specific applications and users of the products but share common pools of technology and infrastructure. This arrangement allows the best possible customer and applications focus with the most effective collective contribution to the overall strength and productivity of the company.

In this presentation only the Industrial Process Control business unit will be elaborated.

For more information, please visit:

https://edir.bulk-online.com/profile...chnologies.htm

http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

berthold_1 (JPG)

■