Dense Phase Pneumatic Conveying

I want some technical clarification in the dense phase conveying. pl anybody can helpme in this regard.

1. what is the relavancy of using Renyolds No in pneumatic conveying and how to calculate Re. No for a particular Powder/ ash

2. How to findout the superficial velocity of any powder in the Densephase pneumatic conveying. for Ex. what would be the S. velocity for the flyash of 0.169mm and 0.146mm mean dia fly ash.

withregards,

arul ■

Re: Dense Phase Pneumatic Conveying

Dear Arul,

The relevance of the Reynolds number of the airflow through the pipe is that the Re-number is involved in the solid losses.

The superficial velocity or suspension velocity is actually best determined by measuring.

A calculation can be made by equalizing the drag force of the particle with its weight under standard conditions.

The floating velocity of 169 micron fly ash is estimated at approx. 3 m/sec.

The floating velocity of 146 micron fly ash is estimated at approx. 2.84 m/sec.

However, the particle Re-number has an influence on the drag factor also.

The particle Re number changes with the slip velocity along the pipeline and thereby the drag factor and as a consequence the suspension velocity changes along the pipeline.

This not only because of the slip velocity but also due to the changing gas density along the pipeline.

Have a nice day

Teus ■

Teus

Dense Phase Pneumatic Conveying

The relevance of the Reynolds number of the airflow through the pipe is that the Re-number is involved in the solid losses.

The superficial velocity or suspension velocity is actually best determined by measuring.

A calculation can be made by equalizing the drag force of the particle with its weight under standard conditions.

The floating velocity of 169 micron fly ash is estimated at approx. 3 m/sec.

The floating velocity of 146 micron fly ash is estimated at approx. 2.84 m/sec.

However, the particle Re-number has an influence on the drag factor also.

The particle Re number changes with the slip velocity along the pipeline and thereby the drag factor and as a consequence the suspension velocity changes along the pipeline.

This not only because of the slip velocity but also due to the changing gas density along the pipeline.

Have a nice day

Teus

Dear Tues,

Fine, Your service for bulk line especially pneumatic conveying is laudable. Our ash collected in the ESPs is conveyed to a big vessel from that the ash is to be conveyed to the RCC Silo located at 1107 m away. To update our knowledge we need your help and guidance.

PHYSICAL CHARACTERISTICS OF OUR FLY ASH

ESPField -1Field -2

Total Ash generation 66 Tons

Collection in ESPs80%20%

Bulk Density in Kg/Cu.M16101296

Sp. Gravity2.702.70

Sieve analysis Report

> 210 Microns45.90%5.07%

150 - 210 Microns12.44%7.03%

75 - 150 Microns14.77%13.35%

< 75 Microns26.89%74.55%

For the ash above specified above, we propose to assume Terminal Settling Velocity Wfo as 0.8 m/sec and Impact and Friction factor s* as 0.011.

For the ash and assumption above, will the use of Weber A4 formula, s = s*C/V + 20 / [ Fr2 C/V] for the solid friction factor is correct. Also will the use of Barth Formula for the pressure drop, ÄP = (f + m*s) LV2/ 2D for the above specified ash and for the pipe layout given is correct.

Product :Fly ashSolid Flow Rate : 66 T/hr

Pipe diameter :300-250-200mmTotal Pipe length :1107m

PIPELINE DETAILS ( from exit)

Pipe section lengthL1m1.00Pipe section diameterD1m0.30

90 deg BendB1 Pipe diameter at Bend m0.30

Pipe section lengthL2m39.00Pipe section diameterD2m0.30

90 deg BendB2 Pipe diameter at Bend m0.30

Pipe section (Vertical)L3m15.00Pipe section diameterD3m0.30

90 deg BendB3 Pipe diameter at Bend m0.30

Pipe section lengthL4m2.00Pipe section diameterD4m0.30

Enlarger 250 mm to 300 mm

Pipe section lengthL5m145.00Pipe section diameterD5m0.25

90 deg BendB4 Pipe diameter at Bend m0.25

Pipe section lengthL6m340.00Pipe section diameterD6m0.25

Enlarger 200 mm to 250 mm

Pipe section lengthL7m16.00Pipe section diameterD7m0.20

10 deg BendB5 Pipe diameter at Bend m0.20

Pipe section lengthL8m12.00Pipe section diameterD8m0.20

10 deg BendB6 Pipe diameter at Bend m0.20

Pipe section lengthL9m230.00Pipe section diameterD9m0.20

90 deg BendB7 Pipe diameter at Bend m0.20

Pipe section lengthL10m65.00Pipe section diameterD10m0.20

10 deg BendB8 Pipe diameter at Bend m0.20

Pipe section lengthL11m10.00Pipe section diameterD11m0.20

90 deg BendB9 Pipe diameter at Bend m0.20

Pipe section lengthL12m185.00Pipe section diameterD12m0.20

90 deg BendB10 Pipe diameter at Bend m0.20

Pipe section lengthL13m36.00Pipe section diameterD13m0.20

90 deg BendB11 Pipe diameter at Bend m0.20

Pipe section lengthL14m3.00Pipe section diameterD14m0.20

90 deg BendB12 Pipe diameter at Bend m0.20

Pipe section length (Vertical)L15m8.00Pipe section diameterD15m0.20

Total 1107.00

If all the above in agreement, I prefer to know the total pressure drop and total air flow (FAD) requirement along with detailed calculation for the given layout and loading conditions.

with regards,

arul rex ■

Re: Dense Phase Pneumatic Conveying

Dear Arul,

The installation, which you describe is capable for approx. 50 tons/hr of flyash.

The compressor size is 60 m3/min and the conveying pressure is 2.5 barg.

The residence time of the flyash in the pipeline is approx. 90 seconds.

It is strongly recommended not to design such an installation yourself but consult a well-known and experienced supplier.

Apart from the design calculation, a number of technical and technological issues can only be addressed by such a manufacturer.

Have a nice day

Teus ■

Teus

Re: Dense Phase Pneumatic Conveying

The installation, which you describe is capable for approx. 50 tons/hr of flyash.

The compressor size is 60 m3/min and the conveying pressure is 2.5 barg.

The residence time of the flyash in the pipeline is approx. 90 seconds.

It is strongly recommended not to design such an installation yourself but consult a well-known and experienced supplier.

Apart from the design calculation, a number of technical and technological issues can only be addressed by such a manufacturer.

Have a nice day

Teus

Dear Tues

The system as explained has already been erected and commissioned, yet the system is under-performing and it is not able to achievedesigned tonnage of 66T/hr. What alterations in terms of air flow and air pressure would you propose for achieveing the required tonnage without altering the layout.

with regards,

arul rex. ■

Re: Dense Phase Pneumatic Conveying

Dear Arul,

For assessing the reason, why the installation is underperforming, it is absolutely necessary to have at least the full information of the system and the actual operating conditions.

The info, which you have supplied so far is not complete.

-feeder system

-compressor size and type

-operating pressure

-actual performance

-altitude of installation above sea level

-ambient conditions

-cooler/dryer

- Other relevant information

How is the pneumatic conveying installation for a length of over 1 km designed?

Are there any calculations available?

Are the design calculations verified with other built installations or different calculation methods?

Are the different quotations technically compared?

Have a nice day

Teus ■

Teus

Re: Dense Phase Pneumatic Conveying

The problem is with the ash classification. The system was probably designed for fine ash

which is very easy to convey in dense phase and the ash size stated here is very coarse /

gritty ash this will not go in dense phase.

Hence the non performance! Solution to the problem is available give some details of the system. ■

Pneumatic Conveying

For assessing the reason, why the installation is underperforming, it is absolutely necessary to have at least the full information of the system and the actual operating conditions.

The info, which you have supplied so far is not complete.

-feeder system

-compressor size and type

-operating pressure

-actual performance

-altitude of installation above sea level

-ambient conditions

-cooler/dryer

- Other relevant information

How is the pneumatic conveying installation for a length of over 1 km designed?

Are there any calculations available?

Are the design calculations verified with other built installations or different calculation methods?

Are the different quotations technically compared?

Have a nice day

Teus

Dear Tues,

Thank you for your remarks. I have given below the details you have asked.

Feeder System : Top discharge twin blow tank of capacity 9Cu.M in series with fluidizing membrane type.

Compressor size and type : Oil free screw compressor with dis.pr-5 Ksc and capacity of 2100 Cu.M / hr.

Operating Pr : 2.6 Ksc

Actual Performance : Able to convey only 30 Ton/hr, When coarseness increases only 20Tons/hr.

Altitude above MSL: Approx 45m from MSL

Cooler type : Heat of Combustion type Dryer , the air temp is around 45ºC

Other Relevant Information :

The system is designed for handling fly ash generated from two power generating units, each generating fly ash of 33 T/hr

Fly ash so generated is collected in two ESPs each with 48 hoppers ( 6 rows X 8).

Ash handling system constitute two sequences of operation, First sequence from ESP hoppers to near by, Common Intermediate Silo( for two Units) and second sequence from Int. silo to far away RCC silo.

First sequence constitute 3 conveying lines of 100m long each( for each unit), two lines of 65/80mm dia convey ash from first row 8 hoppers( 80% of 33T/hr). the third line of 80/100mm dia conveys the remaining ash from the remaining 40 hoppers.

Second sequence line as explained earlier is to convey fly ash ( 2 X 33 T/hr) from Int. silo to RCC silo (1107m)

The first and second sequence ash conveying lines are fed with air from a common header connected to 2 compressors of capacity 2100 Cu.M/hr each.

With regards,

Arul Rex ■

Re: Dense Phase Pneumatic Conveying

Dear Arul,

Mantoo is correct in stating that the fly ash is too coarse for the designed installation.

Calculating the installation results in low capacities and the occurrence of sedimentation.

Increasing the conveying air flow will improve the situation.

Try an extra air compressor of approx. 35 m3/min (F.i. a rental diesel driven plant air compressor at 8 bar with a pressure reducer valve (set at 3.0 bar) (Cvs-value = 17 m3/hr))

Check the filter capacity on the receiving silos.

Success

Teus ■

Teus

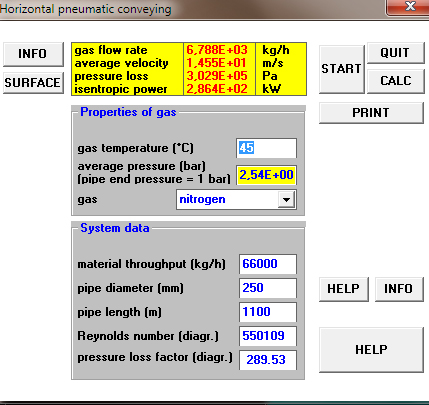

Minimum Conditions For Dilute Phase

To make sure, that the system is working under dilute phase conditions, are after my estimation at least the following operating data necessary, which are confirmed by published data from industrial installations.

href="https://forum.bulk-online.com/attachment.php?attachmentid=43666&d=1429198222" id="attachment43666" rel="Lightbox85746" target="blank">■

Re: Dense Phase Pneumatic Conveying

Manfred

I am unable to open your proggy in a Windows 7 - 64 bit system. Or am I missing something?

Gary ■

Gary Blenkhorn

President - Bulk Handlng Technology Inc.

Email: garyblenkhorn@gmail.com

Linkedin Profile: http://www.linkedin.com/in/gary-blenkhorn-6286954b

Offering Conveyor Design Services, Conveyor Transfer Design Services and SolidWorks Design Services for equipment layouts.

Running Only Under 32 Bit

Dear Mr. Blenkhorn. The software needs a windows 7 - 32 bit system. Possibly it runs on 64 bit systems under the virtuell xp modus that is offered by Microsoft. ■

Dense Phase Pneumatic Conveying

Dear Tues,

I am the regular reader of your answers. your doing wonderful job in the field of pneumatic conveying.

1. Here I like to know the relevancy of using Reynolds No in the Dense Phase Pneumatic Conveying and how to find Re No for a particular ash/ powder.

2. How to find out the superficial velocity of any particular powder.

for example what would be the superficial velocity for the flyash of 0.169mm mean dia and for 0.146mm mean dia.

with regards,

arul ■