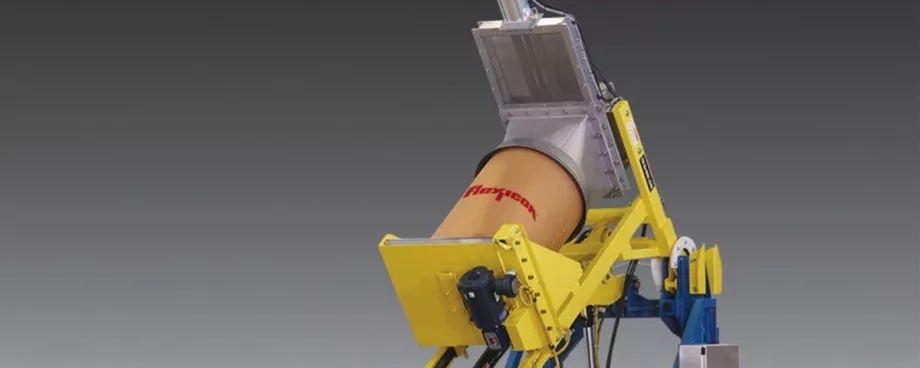

Once full drums are rolled onto the dumping station platform, a hydraulic cylinder raises and seats the drum rim against a discharge hood. A second hydraulic cylinder then tips the drum to an angle of 45, 60 or 90 degrees with a motion-dampening feature. At full rotation, the slide gate opens to allow controlled discharge of material into downstream process equipment.

After the empty container is returned to its upright position, the rolling motion is reversed, and the container is halted in front of a pneumatically-actuated pusher, which transfers the empty drum to the return conveyor for removal. Meanwhile, another full drum rolls into position on the dumping platform.Photoelectric sensors located along the powered roller conveyor relay the position of empty and full drums to the system controller, which actuates the conveyor to advance full and empty drums upon completion of each dumping cycle.The system is also offered in high-lift configurations for dumping into elevated receiving equipment, and in open-chute and dust-free TIP-TITE designs for dumping of boxes, bins, pails and other containers. ■