Re: Uneven Abrasion At The One Edge Of Steel Cord Belt's Inner …

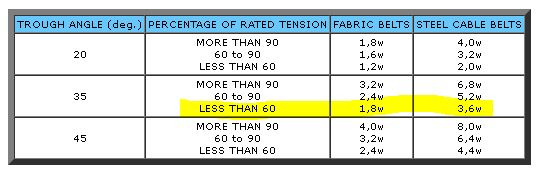

What is the transition distance from the last idler before the head pulley and the tail pulley? This appears to be in the location for possible increased tension due to a poor transition distance particularly at the head pulley where the tension would be the highest. This distance can range from 2.5W to 6.8W (W=belt width) depending on the percentage of full tension at the pulley and if you have a half trough or full trough transition.

Other factors that may show this type of issue is too small of snub diameters and/or too much counterweight (CW). Although 8,000 kg seems reasonable. The snub pulley diameters are borderline for ST1000.

Another possible cause is impact at the loading zone. What is the cover thickness? Was it selected for the handled material (assuming iron ore) and height of the fall to the belt? Is the loading chute designed properly for the least amount of impact on the belt? ■

Gary Blenkhorn

President - Bulk Handlng Technology Inc.

Email: garyblenkhorn@gmail.com

Linkedin Profile: http://www.linkedin.com/in/gary-blenkhorn-6286954b

Offering Conveyor Design Services, Conveyor Transfer Design Services and SolidWorks Design Services for equipment layouts.

Re: Uneven Abrasion At The One Edge Of Steel Cord Belt's Inner …

Thanks for reply Mr Gary,

Transition distance is 5 meter at drive pulley but it is 3 - 3,5 meter at tail pulley. I thougt same thing and we changed chute design at loading zone (loading zone is near to tail pulley)to increase tail side transition distance. It was 2 meter before the change. But after we did that change, problem still didn't disappear. Abrasion was not very dramatic at first times but it went bad at time and here we are. (belt is in operation for 5 years, we changed the chute design 3 years ago)

Material is butimunios coal for thermal power plant. Cover thickness is 8 mm at top and 4 mm at bottom. As i mentioned, abrasion problem is at the one side edge of bottom surface. There are flaps in loading zone chute, it reduces the speed of loading material and let us arrange the loading harmony to avoid belt tracking.

We are aware that snub pulley diameters, esspecially take-up snub pulley diameters are at low limit. Can it be the real reason for it? If it was, then wouldn't pulley rubber lagging also be abraded?

I think, drive pulley (rubber+ceramic lagged) is main reason for that abrasion. But why does this abrasion occurs only at one edge? Also this abrasion is not along the whole length of belt. Length is 550 meter but abraded part is nearly 250-300 meters. Abrasion is not uniform at all area, some parts are more abraded some are less. ■

Re: Uneven Abrasion At The One Edge Of Steel Cord Belt's Inner …

5000mm is at the well below end of the spectrum for transition distance at the head pulley with steel cord belt. 5000/1800=2.8W is more where the tail pulley should be. The minimum you should be is 3.6W or 1800*3.6=6500mm to the first 35 degree idler. See JPG below. Steel cord requires a fair bit more transition distance than carcass belting does.

There should be a 20 degree idler located between the last 35 degree and the pulley and placed so that the vertical distance from top of the pulley to the edge of the belt is .33*Y at the 20 degree idler and Y= the vertical height from the top of the pulley to the leading outside edge of the belt as it passes over the 35 degree idler.

But you are right you should be experiencing this on both sides if this was the issue.

Have you checked to see if the loading chute skirting is of rubber only and not belting? Is it too tight against the belt? Using belting for skirt is very bad as the carcass will wear into the belt as the skirt wears. (Edit - ignore this last sentence as I just realized we are talking about the underside of the belt)

href="https://forum.bulk-online.com/attachment.php?attachmentid=47954&d=1542307638" title="Name: Capture.JPGViews: 162Size: 31.0 KB">Capture.JPG ■

Gary Blenkhorn

President - Bulk Handlng Technology Inc.

Email: garyblenkhorn@gmail.com

Linkedin Profile: http://www.linkedin.com/in/gary-blenkhorn-6286954b

Offering Conveyor Design Services, Conveyor Transfer Design Services and SolidWorks Design Services for equipment layouts.

Re: Uneven Abrasion At The One Edge Of Steel Cord Belt's Inner …

We are using martin engineering apron seal skirts mostly, sometimes we use simple rubber skirt but we don't use fabric belts parts as a skirt. Pressure of skirts on belt is controlled by temperature of contacted area. If pressure is too much, it causes a high temperature at contacted area and then we dismount and arrange it again. Skirt pressure is ok. (u said ignore, i just saw it)

So firstly i should recheck transition distance. Arranging drive side distance to 7 meters and tail side to 5 metre at least. Arranging drive side distance is easy but it looks very diffucult to rearrange transition distance at tail side. Tomorrow i will check exact distance measure and let you know.

Also i wonder, bearing in mind that transition distance is less than it should be, if there was a misalignnent between drive and tail pulley, then aren't there would be abrasion at only one edge of belt? Stress at one edge is bigger than other edge? But if that was the reason, would there be belt tracking problem? ■

Longer Shot

Have you checked how straight the belt is? If it is out of line you can have instability at the take up pulley & the occasional sideway might cause inerference. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Re: Uneven Abrasion At The One Edge Of Steel Cord Belt's Inner …

Mr John,

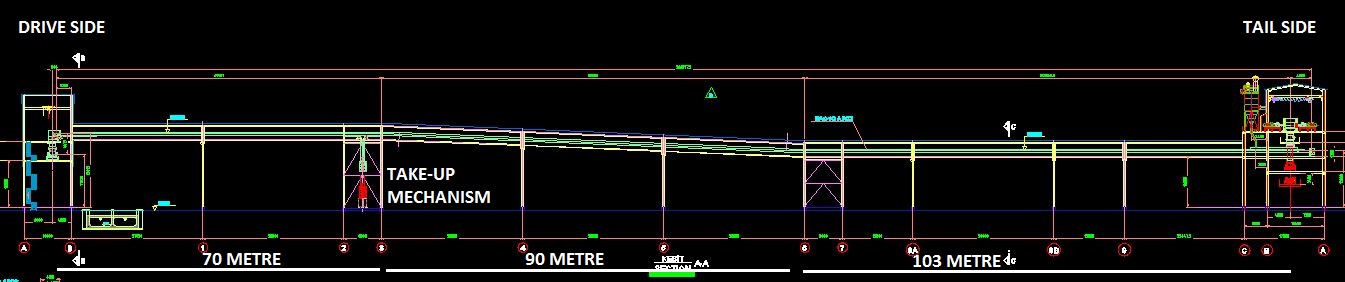

We checked belt and it look straight. Its length is 550 metre and there is 3,2 metre lifting height (from drive pulley to tail side belt is flat 70 metre long and at high position, then there is a part 90 metre long and belt degree is 2,3° downward, and lastly from 160 metre to tail, 105 metre long it is flat again. I added a picture of belt's general view) so it is diffucult check how straight it is. It is also a closed type belt line. We need to designate some cricitical points and then check these points with a total station/teodolit to examine how straight belt is. But i should mention that we checked belt stress from just upper of the take up pulley and we detect that one side's stress is less than other. We couldn't mesaure it numerically, we did this observation with our hands. It is quite possible.

By the way Mr Gary,

As you said we will arrange transition distance as good as we can. It is a ST 1000 - 1800 mm belt, so it should be at least 7 metre. Firstly we did it at drive side and then we will look if we can do it at tail side too with simple design changes.

Thanks for replys and sharing your expreinces/knowledges with me. ■

Re: Uneven Abrasion At The One Edge Of Steel Cord Belt's Inner …

Hello,

Participants have already mentioned number of possible causes. You may also look for following possibilities (consider these as thoughtful guessing):

- Belt inner surface (bottom cover side) is having wear (abrasion mark) problem. So you may see whether anything wrong with internal scraper.

- See for belt slippage during starting.

- Belt inner surface rubbing anywhere with some structure.

- Belt alignment condition at head, tail and take-up, during running condition.

- Whether conveyor is perfectly straight in horizontal plane.

- Whether head and tail pulley shafts are exactly at right angle to belt general path. Also pulleys alignment at take-up that is their position with respect to belt.

- Whether conveyor has travelling tripper. If so, see that belt is not rubbing with any item in tripper.

- Possibility of any mischief.

Ishwar G. Mulani

Author of Book: ‘Engineering Science And Application Design For Belt Conveyors’. Conveyor design basis is ISO (thereby book is helpful to design conveyors as per national standards of most of the countries across world). New print Nov., 2012.

Author of Book: ‘Belt Feeder Design And Hopper Bin Silo’

Advisor / Consultant for Bulk Material Handling

System & Issues.

Pune, India. Tel.: 0091 (0)20 25871916

Email: conveyor.ishwar.mulani@gmail.com

Website: www.conveyor.ishwarmulani.com ■

Re: Uneven Abrasion At The One Edge Of Steel Cord Belt's Inner …

Hello,

I add following to my earlier reply:

If the conveyor has concave curvature, then see whether return belt lift up at that location and rub with the under side of carrying idlers, during starting, steady running and particularly stopping (head end drive with strong brake may create surge in tension at that place during stoppage).

Ishwar G. Mulani

Author of Book: ‘Engineering Science And Application Design For Belt Conveyors’. Conveyor design basis is ISO (thereby book is helpful to design conveyors as per national standards of most of the countries across world). New print Nov., 2012.

Author of Book: ‘Belt Feeder Design And Hopper Bin Silo’

Advisor / Consultant for Bulk Material Handling

System & Issues.

Pune, India. Tel.: 0091 (0)20 25871916

Email: conveyor.ishwar.mulani@gmail.com

Website: www.conveyor.ishwarmulani.com ■

Uneven abrasion at the one edge of steel cord belt's inner surface

Hi mates

There is uneven abrasion at the one edge of our belt's inner side. We checked all rollers, pulleys and v type cleaners but couldn't find a reason.

All advices would be appreciated.

ST1000 (8+4) 1800 mm, abrasion resistant type. Belt length is 550 m (distance between drive and tail pulleys is 267 metre)

Drive pulley is lagged ceramic+rubber, other pulleys (tail, tail snub, drive snub, take up snub pulleys and take-up pulley) are rubber lagged.

Belt capacity is 4000 ton/hour but we mostly use it at 2400 ton/hour capacity. Belt speeed is 4 m/s but we mostly use it 3,5 m/s (vvvf so we can arrange speed as we desire)

There are impact rollers at tail loading area. Other rollers are 35 degree, standart metal rollers. Return rollers are rubber rings type and all are 2000 mm, there aren't any v type return roller.

Take-up weight is nearly 8.000 kg / 8 ton. There is a rotation check sensor (antipatinage or antskid) at tail pulley.

Pulley diameters are; drive 1000 mm, tail and take-up 800mm, tail snub an drive snub 500 mm, take-up snub pulleys 630 mm.

href="https://forum.bulk-online.com/attachment.php?attachmentid=47953&d=1542278089" title="Name: 4.jpgViews: 169Size: 92.2 KB">4.jpg ■