Re: Compressor Power

dear dror,

Compressor power is calculated along the thermodynamic laws and formulas, appropriate for the type of compressor in question.

Types of compressors are:

-positive displacement without internal compression (Roots-type blowers)

-positive displacement with internal compression. (screw compressor, vane compressor, water-ring compressor, piston compressor)

-Turbo compressors

Additionally, it is important whether the internal compression is isochoric (blower), adiabatic, isothermal or a combination of these. (depending on the internal compression ratio and the delivery pressure)

Compressor suppliers state the power requirements of their compressors in the data sheets.

Also auxiliary equipment to the compressor is important.

If you can inform us of the compressor, you might be referring to, we can help you more specific.

The compressor choice is a very important choice, because it influences the energy costs.

A buffer tank calculation spreadsheet is attached.

best regards,

Attachments

■

Teus

Re: Compressor Power

Why calculate it?

If you are buying a compressor for a specific duty the manufacturer will supply it with the correctly sized drive motor. ■

Re: Compressor Power

Originally posted by dror

How do you calculate compressor power given the pressure and capacity (volume per minute).

I obviously know how to compare suppliers tables for motor size for a given compressor duty.

I am interested in the thermodynamic aspect of the compression process and would like to examine it for a two stage screw compressor with an intercooler.

Will appreciate your help.

Regards,

Dror. ■

Re: Compressor Power

Purely academic textbook detail thread.

I worked for a compressor manufacturer in Hemel Hempstead who made any stage screw compressor packages driven by electric, diesel & wet process steam. In all that I never gave a toss about the thermodynamics.

This question is best answered by self help at a city library. Hick Hargreaves handbook is a good place to start. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Compressor

To add to johns reply you also need to add the altitude that the compressor is going to be working at to add this to the mix of data. ■

Re: Compressor Power

Dear dror,

If you want to combine two screw compressors into a 2-stage compressor set, the following has to be clarified.

Type of screw compressors

Internal compression ratio

Oil free or oil filled.

Oil free (compression ratio approx. 4 , not cooled, adiabatic compression)

Oil filled ( compression ratio approx. 8-10, cooled, isothermal compression)

If stage 1 delivers the air compressed (cooled) at the intermediate pressure, then that delivered volume is the intake of the 2nd stage.

The 2nd stage compressor has to match that volume, otherwise the intermediate pressure will change and thereby the load of the compressor stages.

This is quit a complicated matter (though very interesting), but should be left to the experts, dealing with compressors daily.

This requires the full knowledge of thermo dynamics.

Success

PS As I disciovered an error in my file in cell G4, hereby an update.

Attachments

compressed-air-vessel_update (ZIP)

■

Teus

Power Of Blower

is there anyone helps me on my project...

my question is...

is there any method to calculate the power of blower without having any given data.... ■

Re: Compressor Power

No. Do you know what calculations are? ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Re: Compressor Power

Dear Mr Ahsan,

One data, you have, is that your subject is a blower.

The working principle of a blower is :

a positive displacement compressor with isochoric compression.

As the performance of a compressor is set by the intake conditions (suction or atmospheric), the appropriate formulas are as given below.

Positive displacement pumps

Characteristic data for a blower are :

p1 = pressure at inlet

p2 = pressure at outlet

q0 = internal displaced volume per rotation

n = number of rotation per minute

Q0 = internal displaced volume per unit of time

Qv100 = internal leakage-losses at a dp of 100 mbar per unit of time.

Qv = internal leakage-losses at dp per unit of time

Q1 = External displaced volume at p1 per unit of time

Roots-type blower :

Q0 = n * q0

Qv = Qv100 * SQRT ((p2-p1) * 1,293) / (100 * rho(l)))

in which : rho(l) = 1,293 * p1 * 273/(273+t(amb))

follows :

Qv = Qv100 * SQRT ( ((p2-p1) * (273 + t(amb))) / (100 * p1 * 273))

Q1 = Q0 - Qv

eta(vol) =Q1/Q0 = (Q0-Qv)/Q0

P(th.dyn) = Q0 * (p2-p1) (isochoric compression)

P(shaft) = P(th.dyn) + P(losses)

As Mr John Gateley stated, no calculations without figures.

But, if you pose a question, you must have a real issue at hand, to which your question relates. If you explain that real situation to the forum members, a more specific advise can be given.

success ■

Teus

Re: Power Of Blower

Originally posted by ahsan

is there anyone helps me on my project...

my question is...

is there any method to calculate the power of blower without having any given data....

The olny safe way to calculate the power of a blower depending on its size is the proper use and calibration of a "milking machine vacuum gauge"-

a good brand is "Delaval".

The calibration that must be done is adjusting the readings for sea level measurement to obtain true readings dcepending entirely upon blower or vacuum service use.

It also helps if you have the numbers off the blower frame identification tag as to blower size etc. other wise it is useless with out the "milkhouse vacuum gauge" ■

Re: Compressor Power

"my question is...

is there any method to calculate the power of blower without having any given data.... "

Is there any way to do a calculation without any data???? ■

Compression Power

If you want a quick first approximation solution to compressor power try using:

Power = 202 x volumetric flow rate at free air conditions in m3/s x the natural logarithm (ln) of the ratio of delivery pressure to inlet pressure (both as absolute pressures in any units) and this will give the answer in kW. If you have the air flow rate in kg/s rather than m3/s replace the constant 202 with 165.

Pneumatic conveying can be very energy intensive, particularly for long distance and high tonnage conveying. If the power required is multiplied by the cost of electricity in cents/kW-hour you will get the approximate cost of running the system. If this does not frighten you then go ahead with a complete design and get an accurate assessment of power required from the compressor manufacturer. ■

Re: Compressor Power

dear all

I think that mr Izaharis assumes that mr Ashan has a blower.

In that case it is necessary to measure the flow per revolution, which should be possible with the “milking machine vacuum gauge” .

(Delaval site did not give me a clue how that works, but I believe that it is possible)

From there, the formals, I gave, can be applied.

success

PS Calculations of an existing blower can be done with given data.

In case no data are given you can measure the data, as long as you have a blower.

Reading the name plate will help, as well as asking an experienced field engineer or mechanic, who will reckognize the blower brand and type. ■

Teus

Re: Compressor Power

Hi,

I realise the reply is a year late, but I had the same problem and found a useful doc. on the net. So I thought I'd post a reply a bit more useful than "not giving a toss about thermodynamics":

href="http://www.vairex.com/pdf/Efficiency-0523.pdf" target="blank">http://www.vairex.com/pdf/Efficiency-0523.pdf

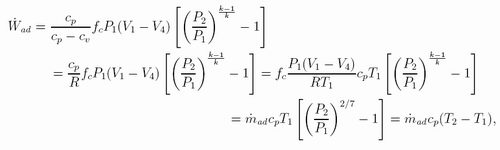

The power requirement for adiabatic compression can be found from the attached formula (snapshot taken from the doc. found above)

Attachments

compression_power_formula (JPG)

■

Compressor Power

Thank you abitmad for long awaited reply.

The suggested link in your reply provides the exact answer to my question.

Dror. ■

Compressor Related

dear Teus Tuinenburg

u have given some calculation which i presume to be a sizing of air receiver

if u r ready to help me , ihave come point to be asked

1 what yellow, green boxes indicates is it constant

2 what does alpha mean

3 if i need to get sizing say size of receiver req for 500cfm at 7 bar than where ineed to feed these input in cour calculation format

plz help me ■

Re: Compressor Power

dear rahulchaubey,

yellow cells are for your input values.

other colored cells are calculated values

red cells are warnings

Alpha means the usage factor of the compressor

units are metric according to ISO (not cfm)

500 cfm = 14.16 m3/min

sizing the receiver depends on :

1)air consumption

2)required ON/OFF times of compressor or number of starts of compressor

3)allowed pressure differential range

4)allowable usage factor of compressor.

Attached the spreadsheet file with the comments in each cell, to make it easier to find your way in the spreadsheet.

success

teus

Attachments

■

Teus

Re: Compressor Power

kind attention:- Teus Tuinenburg

dear sir as per your mail u have given the calculation which i presume wud be the calculation of receiver capacity at 500cfm=15m3/min at 7 bar

According to u uhve converted it into standard condition is 106m3/min suction volume at 101.325kpa , out of which calculated value from your excel is something 20m3 .

But as per my experience volume for air receiver should not be more than 3 m3 , either iam not getting your calculation perceive or imay be wrong . Plz help me to indicate exact volume of 15m3/min of compressed air

also specify what green colour indicates ■

Re: Compressor Power

dear rahulchaubey,

yellow cells are for your input values.

other colored cells (like the green cells) are calculated resulting values

red cells are warnings

I did not fill in your case in the spreadsheet, but I did that in the attached file.

13.5 m3/min consumption at 7 bar, results in a compressor of 15 m3/min at 9 bar and a usagefactor of 0.9

You can vary the values in the yellow cells as you like and judge the resulting calculated values.

success

teus

Attachments

compressed-air-vessel15m3 (ZIP)

■

Teus

Re

DEAR Teus Tuinenburg

ONCE AGAINTHERE IS BIG CONFUSSION WITH ME

AS U ARE CONSIDERING 13.5M3/MIN AT ATMOSPHERIC PRESSUE

BUT AS PER MY DATA 13.5M3/MIN IS AT 7BAR WHICH GIVES 105M3/MIN AT 1 BAR. NOW IF SUCH(ATMOSPHERIC CONDITION) INPUT HAS TO BE ENROLLED IN YOUR SHEET THEN VOL SHOULD BE CONSIDERED 105M3/MIN ACCORDING TO ME

PLEASE FORGIVE IF IAM WRONG

2 ALSO LET ME KNOW THE METHOD OF USING THIS CALCULATION

IMEAN WHAT INPUT AND WHERE IHAVE TO PUT IT IN YOUR SHEET TO GET REQ VOLUME OF RECEIVER AT 13.5M3/MIN @ 7BAR ■

Re: Compressor Power

Dear Mr rahulchaubey,

If your air consumption of the installation is 13.5 m3/min at 7 bar(o), you are correct, that will be 105 m3/min at atmospheric conditions.

(Normally a compressor is indicated by its free air delivery at a certain pressure)

To comply with your definition (105 nm3/min air consumption compressed to 7 bar(o)),

you can enter the following values:

Cell – Input

G2 – 105

J2 – 7

G3 -0.9

G4 – 20

G5 – 25

G6 – 10.5

G7 – 8.5

L5 – 25

L6 – 8

C13 – 116.67

The result is 15.5 starts/hr (ON/OFF cycles)

Note : Pay attention to absolute or over pressure values.

If you switch off the cell protection, you can figure out how it works by the cell content,

although that will not be easy.

Also read carefully the cell comment, by bringing the pointer over the cell.

The formulas used are the normal gas laws.

success

teus ■

Teus

Compressor

DEAR Teus Tuinenburg

i really embraced getting your continues reply.

referring to your given calculation an outcome result is time related ie 15.5starts/hr related to same ihve some queries which icud expect to be clear by u.

1 what input and where i shud enter in given calculation to know the required volume of receiver if compressor capicity is same ie 15.5m3/min

2 plse let me know wat is 15.5starts/hr

3 What FAD stands for, is it capacity of compressor at atmospheric condition, thatswhy it is indicated by NM3/HR ■

Re: Compressor Power

Dear Mr rahulchaubey,

1)If you have a compressor of 15.5 nm3/min of free air delivery (FAD) and a (chosen) usage factor of 0.9, then you should enter the value of 15.5 * 0.9 =13.95 nm3/min into cell G2

By changing cell G4 (receiver volume), the ON/OFF cycle period is calculated. (as well as the rest of the parameters)

Notice also the drawings.

2)15.5 start/stops per hour.

As the compressor pumps more air than the installation consumes air, the pressure in the receiver tank increases until a set maximum pressure is reached.

At that moment the compressor stops delivering air. (STOP)

The installation air consumption is then delivered by the receiver tank only and the pressure decreases until a lower set pressure is reached.

The compressor starts delivering air again (START)

This starting and stopping takes place in the example 15.5 times per hour.

3)With FAD (Free Air Delivery) is the volume meant ththat a compressor takes in at its inlet, thus at atmospheric conditions.

In the spreadsheet, the values are calculated back to nm3/min (standard conditions : 1 bar and 0 DegrC)

take care

teus ■

Teus

Compressor

Dear:- Teus Tuinenburg

sir tonns of thnx for your mail

but my worry is wat and where shud i enter in your sheet to get the entire volume for receiver

capacity of compressor remains the same ie 15m3/hr @ 7 bar

regards

rahul ■

Re: Compressor Power

Dear mr rahulchaubey,

You are welcome.

The only cell where you can enter the volume of the receiver is cell G4.

As this cell is free to change, the other parameters can be influenced until an acceptable value is reached. (f.i. the number of start/stops per hr)

The spreadsheet is used as an iterating system.

Again, take into consideration the definitions of the values you use.

(15 m3 at 7 bar = 15*8=140 Nm3 at 1 bar(absolute))

have a nice day

Teus ■

Teus

Compressor

Dear:- Mr Teus Tuinenburg

Tonns of thnx for your reply

here i got some more point to be cleared if u r ready

1) FAD in compressor presume intake air of air compressor at atmospheric condn

Let us take an exmple

What is FAD of compressor deliver air 500cfm @ 7 bar

500cfm means 13.8m3/min

According to me its FAD shud be 13.8x7=19.6nm3/min

Here is some cinfusion if iam right

to convert m3/min into nm3/min we multipli m3/min by 1.15

then 13.8x1.15 comes 17.8m3/min which does not equal to 19.6m3/min

Plz explain me ■

Re: Compressor Power

Dear Mr rahulchaubey,

Definition of FAD is correct.

A compressor that delivers 13.8 m3 at 7 bar(overpressure)

has. a FAD of approx 138 * (7+1) = 110.4 m3 at 1 bar(absolute)

You can calculate all these volumes and pressures by using the relation:

p * V / T = constant.

or

p1 * V1 / T1 = p2 * V2 / T2

p = pressure in bar(absolute)

atmospheric pressure = 1 bar(absolute)

T = temperature in degrees Kelvin

V= volume in m3

For p=1 and T=273 the volume is in nm3

Success ■

Teus

Compressor

Dear Mr Teus Tuinenburg

Here is some more for u

If FAD OF 13.8m3/min is 110m3/min

now if suppose i have to convert directly 13.8m3/min into nm3/min that means ihve to multiply it by 1.15 dat comes 13.8x1.15=15.9nm3/min is dis will be FAD of same becoz its unit is Nominal m3/hr

but is not = 110m3/min which we calculated from the formula if P1V1=P2V2 ■

Re: Compressor Power

Dear Mr rahulchaubey,

nm3 is the volume at 1 bar(ABSOLUTE) and 273 degr.K.

nm3 is an abreviation of normal m3 or, in english units, SCFM.

I am not aware of your factor 1.15 , but I assume that you are referring to the specific mass of air at 34 degr.C (307 degrK)

The density of air is calculated as:

density of air = 1.293 * p(abs) * 273/(273+t)

t = temperature in degr.C

As 13.8 m3 is at 8 bar(abs), the specific mass is:

1.293 * 8 * 273/307 = 9.2 kg/m3

Total mass of air = 13.8*9.2 = 126.5 kg

Or 110 m3 is at 1 bar(abs), the specific mass is:

1.293 * 1 * 273/307 = 1.15 kg/m3

Total mass of air = 110 * 115 = 126.5 kg

All for now

teus ■

Teus

Re: Compressor Power

Dear:- Teus Tuinenburg

which is this formula

density of air = 1.293 * p(abs) * 273/(273+t)

what is 1.293 ■

Re: Compressor Power

Dear Mr rahulchaubey,

1.293 is the density of air in kg/m3 at 1 bar(absolute) and 0 degr.Celsius.

The formula calculates the density of air in kg/m3 at a pressure p(abs) in bar and a temperature t in degr.C

(what is your factor 1.15 representing?)

best regards

teus ■

Teus

Compressor

Dear:- Mr Teus Tuinenburg

tnx sir

your formula made me perceive that 1.15 factor may be the density at atmospheric condition, that means to convert m3/hr into nm3/hr we have to use formula p1v1=p2v2 is isnt it.

That means if we need to conevrt cfm inti scfm then once agin we have to consider th same p1v1=p2v2

m i right ■

Re: Compressor Power

Teus Tuinenburg

sir

here is one more thing related to ash i want to ask

coarse ash is more dense than fine if iam correct with my assumption than what is the reason which makes coarse becoming more dense than fine ■

Compressor Power

Hi, somebody knows this formula???

HP= Q * 63 * Ln(Pd/Ps)

Is a rare formula that are been used in a pipeline gas.

Thanks.

Felipe

PD: Sorry if I make a mistake in the english, I speak spanish. ■

Re: Compressor Power

Dear Felipe,

This formula calculates the power for compression at constant temperature. (isothermal)

It is not a rare formula.

Have a nice day

Teus ■

Teus

Centrifugal Compressor Ta6000

i want to calculate the change in cooling water temperature for the two intercoolers and aftercooler and i only have the inlet cooling water temperature and i need the method to get the outlet temperature. i also have the outlet pressure, flowrate and temperature of the air, as well as the inlet temperature, pressure, flowrate of the air. system power and pressure. ■

Re: Compressor Power

Dear mfondez,

You are referring to a Cooper Compression TA 6000 turbo compressor with intercoolers.

The intercoolers are part of the compressor assembly.

The after cooler may be of the same manufacturer or not.

Calculating temperature changes in mass flows is performed by equalizing the transferred heat energy.

Therefore, you need to know the respective gas conditions p, V and T, the gas constants and gas flow as well as the water mass flow.

The transferred heat is then: Hgas = cp * gas mass * dTgas (assuming that the pressure in the cooler is constant)

The transferred heat for the water is then Hwater = cwater * water mass * dTwater

Equalizing gives:

cp * gas mass * dTgas =cwater * water mass * dTwater

or

dTwater = cp * gas mass * dTgas / (cwater * water mass)

Reading the compressor manual or consulting the manufacturer saves a lot of effort.

Calculating the heat exchangers themselves is more complicated.

Success

Teus ■

Teus

Compressor Power

Hi Dude, pv(nx divide by n-1)[{p2 divide by p1}exp.(n-1 over nx) -1]=work done by the compressor per cycle or per min. or per sec(depennds on your rate of air intake). power to drive the compressor=[wd(cycle) x 100%] divide by mechanical efficiency of the compressor.Good day Dude.

Hlaxx ■

A/C Compressor Power Calculation

dear all i want know how we calculate power of an A/C compressor which is driven by engine. ■

Re: Compressor Power

Dear Furcan,

If you are referring to an Atlas Copco compressor then act as follows:

Look at the name plate of the compressor-set, compressor and diesel engine.

Probably you have the power then already.

If not, then visit the website of Atlas Copco, search for the compressor and verify the data.

Calculating something without knowing the input (volume/rev, rpm, intake conditions, pressure) is useless.

Success

Teus ■

Teus

Compressor power

How do you calculate compressor power given the pressure and capacity (volume per minute). ■