Timing

You have put the cart before the horse.

Fluidising pressure should have been added when the silo was designed. Point this simple fact out to those who blundered into management.

Otherwise you are sticking your neck out for somebody else.

Sorry to be so blunt but that is the situation. Neither you, nor your management, can hope for a recommendation for such a task based on rudimentary information ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Re: Pressure Required For Fluiding Blower Installed On Fly Ash …

John,

You assume that the silo was designed and built as a fly ash silo first and then then the fluidization system was forgotten.

Looking at the dimensions of the silo (Diam=13 m Height=15m) it could also be a used oil tank from a powerplant or a refinery or whatever.

Considering the dimensions, it must be a flat bottom tank (silo) in which approx. 2000 tons fly ash can be stored.

(I saw 2 old oil tanks from a powerplant in Dordrecht, the Netherlands being re-used in Antwerp for cement storage. I think it was in the late 90’s or short thereafter)

Then, the situation can arise that you have the tank first and then must cope with the conversion to a fly ash storage.

It is possible.

Re-using a used tank for a different commodity requires at first new strength calculations where asymmetric wall loading is essential.

The question of sgoel was about fluidizing a silo, storing fly ash.

Here, the first misconception arises.

A full silo is initially not fluidized but aerated.

When the silo reaches the empty condition, fluidization starts.

The required aeration air flow in m3/min.m2 is always less than the required fluidization airflow in m3/min.m2. (typically 0.43 m3/min.m2 for fluidization and 2 m3/min.m2 for fluidizing)

The required aeration air flow pressure in barg is always higher than the required fluidization airflow pressure in barg.(typically 0.3 barg for aeration and 0.0 barg for fluidizing)

The percentage of aerated- or fluidized bottom area can be selected to find the optimum blower configuration.

After designing an aeration/fluidizing system, the work is far from over, because then you have to focus on the extraction system and outflow control.

Otherwise you are sticking your neck out for somebody else.

Is this not always the case? ■

Teus

Why Fluidisation With An Hygroscopic Bulk Material?

Hello

Have you considered other options to unload your silo/bin?

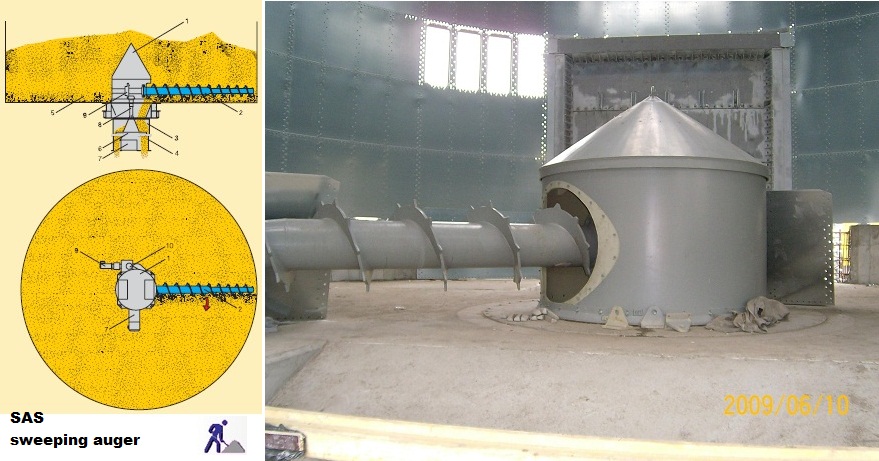

In case of an flat floor you may think about sweeping augen, which pulls the bulk to the center to the chute.

See the picture:

Disadvantage: higher purchase costs

Advantage: * it is dry :-) + does not need that much energy; it is quite wear resistant + mass flow with full silo and with quite empty silo (nothing remains)

See the video:

b.rgds

dak

T +1858 5644045

M +54911 53252311

E bulk.good.solutions@gmail.com ■

Pressure required for fluiding blower installed on Fly Ash Silo

Dear Team

I am required to design a fluiding system for a silo storing fly ash. Details of silo are:

Diameter: 13 meters

Height 15 meters

What would be the basis for sizing the blower (flow and pressure) for this application?

Thanking you in anticipation please.'

S Goel ■