Re: Corrosion Properties

And TSP is ....??

I certainly recall seeing an elevator that handled ammonium chloride where all the surrounding walkways and access ladders were wood. ■

Tsp

Our customer calls it Triple Super Phosphate, although a google search also has TSP as TriSodium Phosphate. The material we are used to handling are potash, urea, SAP (single amonium phosphate) and DAP (Dual amonium phosphate). They are corrosive but epoxy based paints and 304 SS protect steel and aluminum parts very well, but this stuff is nasty. ■

Re: Corrosion Properties

Hallo

I don´t know whot axactly do you need to protect, but for pipes and transport we are using basalt.

Basalt resist overwhelming majority of acids and alkaline solutions, only hydrofluoric acid which dissolves it, because the basalt is based on silicates.

We got him a very good experience in Russia for the transport of potassium salts, or crude oil, which contains both sand and many compounds from sulfur to hypochlorite.

Can you sand more detail info whot exactly do you have to solve.

Vaclav Kohout

kohout.vaclav@centrum.cz ■

Thanks For Your Reply

Interesting, basalt is definitely not something I would have thought about. I have read the properties of the material and it does produces Fluorine Gas when it gets wet ( which it would in an outdoor application like the one in question). I will keep your idea in mind, since we deal with all kinds of corrosive materials. ■

Re: Corrosion Properties

I have been involved with the salt industry for over 30 years and have tried many coatings and materials to prevent the galvanic reactions and corrosion to steel including sacrificial anoding.

When I came across Devtar 5A by Devoe Coatings (see link below) I found that it works very well for our environment. Only other alternative for us was 316 Stainless Steel and you don't want to go down that costly road. We also have used fiberglass structural components but when maintenance and cutting torches are involved (as in most opertations) the fiberglass was not always the best around slag from cutting.

The main secret to applying any epoxy coating is a very good blast cleaning to SSPC 10 near white and then the application of two coats 8 mil DFT imediately following the blasting.

Believe me when I say I have tried everything.

Attachments

■

Gary Blenkhorn

President - Bulk Handlng Technology Inc.

Email: garyblenkhorn@gmail.com

Linkedin Profile: http://www.linkedin.com/in/gary-blenkhorn-6286954b

Offering Conveyor Design Services, Conveyor Transfer Design Services and SolidWorks Design Services for equipment layouts.

Alumina Ceramics

CBC supplies alumina tubes, cyclone, cone, blocks, tiles for wear protection.

Zhanghongbocbc@163.com

----------------------------------

http://aluminaceramics.blog.com ■

Re: Corrosion Properties

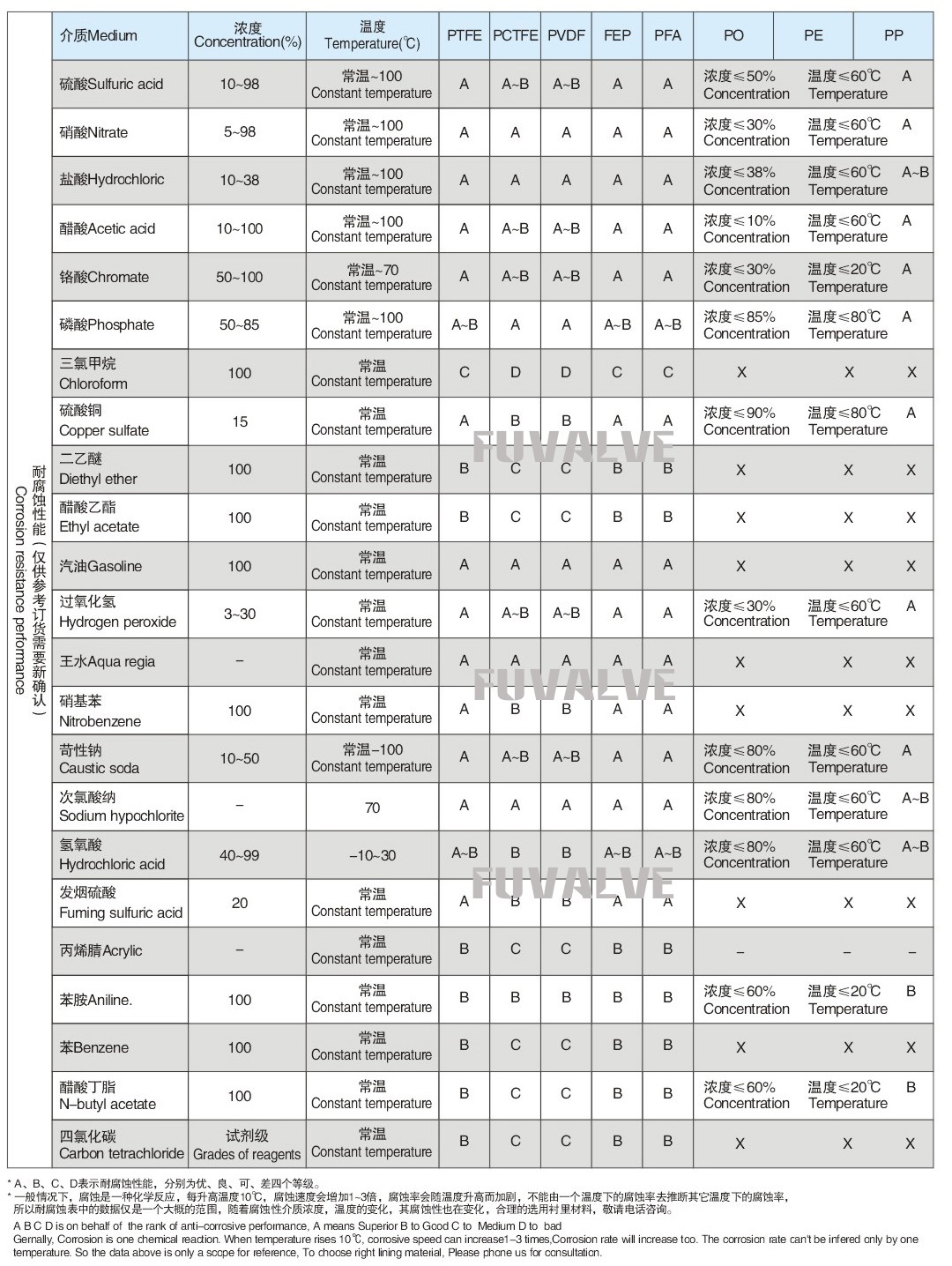

Here I attach the corrosion properties for differen materials for your information. ■

Re: Corrosion Properties

Alumina ceramics / Zirconia ceramics / ZTA

Supplier of advanced ceramics since 2004

https://aluminaceramics.wordpress.com ■

Corrosion Properties

Does any one know of a table or resource that describes the corrosion characteristics of various compounds? We will be working in an area with TSP, which is a phosphate product that I remember sometimes used wooden conveyor supports because it destroyed everything except 316. I was trying to find some documentation on it and DAP. ■