Building materials have their own specific characteristics, such as high product temperatures or different volumes and weights _ they may show an unusual flow behaviour and may be dimensionally unstable. As a partner to this industry, Beumer Group successfully enable material manufacturers to fill bags without any product loss with their fillpac filling machine. The systems of this construction series fill reliably, carefully and sustainably while meeting the required throughput.The machine is equipped with a weighing unit, which communicates permanently with the filler neck via a dedicated software. The automatic bag weight control determines the exact filling weight while filling thus always achieving accurate degrees of filling. The packaging line works more efficiently as it is no longer necessary to remove under or overweight bags from the material flow. In addition, the quantity indicated on the bag always corresponds to the real volume.

Pourable and coarse-grained Material: Air Filling Machines

Depending on the requirements and on the material characteristics such as bulk density, flow behaviour or grain distribution, Beumer can offer both air and turbine filling machines from the construction series. The air filling machines are suitable for bagging pourable and coarse-grained products with particle sizes up to ten millimetres.The systems use a blower to fluidise the materials in a pressure chamber. The products can then be filled into bags gently and precisely. Depending on the throughput, the user may opt for a rotary or an inline filling machine. The air rotary filling machines have four to twelve filling modules which are arranged in a circular pattern. Depending on the number of filling spouts, the systems reach a maximum capacity of 1200 to 3600 bags per hour for 25-kg bags.

The air inline filling machines are generally equipped with one to four filling modules. Depending on the number of filling spouts positioned next to each other, the system achieves a capacity reaching between 300 and 1200 25-kg bags per hour. Regardless of whether the system is arranged in a circular pattern or in a line, capacity and utilisation can be improved by installing an optional automatic bag placer.The filling process is carried out either automatically or at the push of a button. Two configurations are available for removing the bag at the end of the filling process: either manually or automatically with vertical bag discharge on a belt conveyor.

Free flowing and fine-grain Products: Turbine Machines

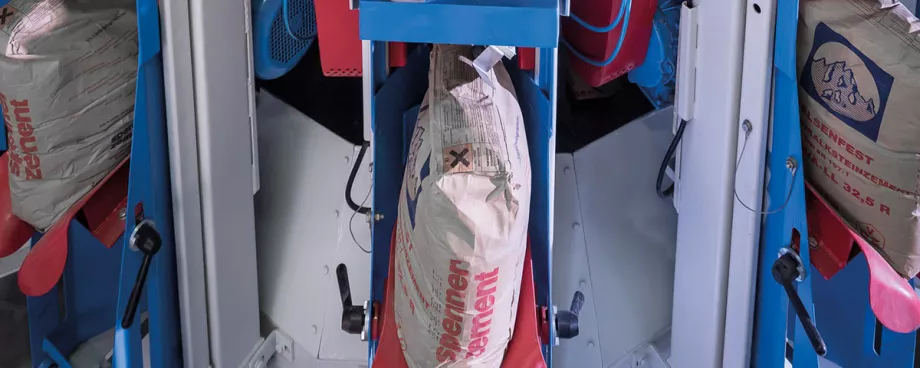

The turbine process is the appropriate solution for companies which predominantly fill free flowing and fine-grained materials, such as cement or gypsum. The turbine filling machines use motor-driven impellers. They can be arranged either horizontally or vertically, ensuring a particularly high filling pressure and thus a very good compaction of the fine-grained materials to be bagged. The result is filled bags which are compact and dimensionally stable so that the user is no longer required to vent them.With up to 20 filling modules, a fillpac R for example can fill up to 300 tonnes of fine-grain materials per hour into diverse bag types. The optional HDPE bag placerenables dependable filling of HDPE bags. The filling impeller is characterised by its speed and the maximum material throughput. The bag weight adjustment, which automatically adjusts the weight of the next bag, always ensures precise results.Opening and closing of the vertically mounted filling spout is carried out outside of the dirty area _ this way the three-position cylinder which regulates the coarse and fine flow is protected from dust. The cylinder for bag discharging is also located in the dust-free zone above the filling spout. This solution minimises wear and tear on both cylinders and, therefore, ensures longer service life.The turbine filling machines are also offered with inline design. The filling modules are placed next to each other for ready access, which makes them extremely easy to maintain. The inline filling machines are best suited for production environments with low throughput rates.

Individual Customisation

The Beumer construction series is equipped with an ergonomic control terminal. The improved Human-Machine-Interface concept allows operators to work in a simple and intuitive way. Almost all built-in components of the fillpac are freely available commercially. This reduces delivery times for spare parts and lowers capital costs for the user. Furthermore, the intralogistics supplier has designed the system in a way that individual customer requirements or special operational requests can be implemented flexibly and cost-effectively.

| About the Author | |

| FirstName LastNameMarketing ManagerBeumer Group GmbH & Co. KG, Germany |

■